Novidrill EDM Drilling Machines

Affordable Quality EDM Drilling Machines

EDM Hole drilling

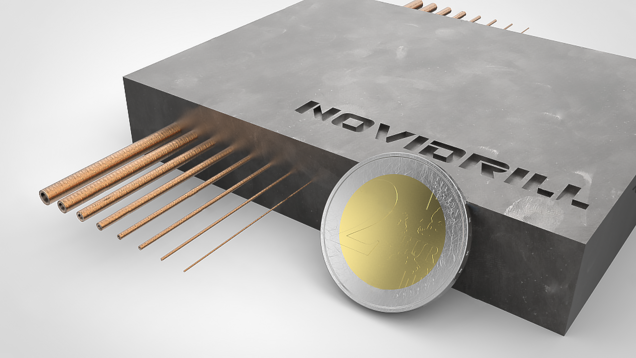

Our Novidrill EDM Rapid hole drilling machines use low cost electrode tube (normally brass or copper material) to drill holes on a electrically conductive material at a very high speed, the hole depth diameter ratio can reach up to 300. The hole diameter is normally from 0.3mm to 3.0mm, the machine can drill holes on a inclined surface workpiece. This technology is widely used for hole machinig in aerospace, energy, cutting tools, automotive, medical, mold and die industries.

High-speed EDM hole drilling was designed especially for fast, accurate small- and deep-hole drilling applications. Small holes that were once almost impossible to drill by conventional machine tools are now being performed with ease. With the capability of drilling through virtually any conductive material, the use of this technology is continually expanding.

Considered a last resort for drilling holes, Fast Hole EDM Drilling (Electrical Discharge Machining) is quickly becoming the standard method for producing small, tight tolerance holes. It is an extremely cost effective method for producing fast and accurate holes into all sorts of whether hard or soft conductive materials.

MAIN FEATURES:

• Compact space-saving design with integral dielectric system and generator for machining of small and medium-size parts

• Machine casting frame uses high quality cast iron, heat treated for stress release to keep machine body high rigidity without deformation.

• Machine construction according to computer analysis of tensile strength, compression resistance and stiffness strain.

• Highly accurate spindle head with the quill running on pre-loaded cross roller bearings

• Servo drive - step motor on Z axis for reliable control

• Manual central lubrication for table guides and spindles

• User-friendly, easy to learn operation; parameters are entered directly in the control panel and can be easily optimized.

Today’s most economical solution for producing high precision and high-speed holes.

Fast Hole EDM Drilling is quickly becoming the standard method for producing small, tight tolerance holes. It is an extremely cost-effective method for producing fast and accurate holes into all sorts of whether hard or soft conductive materials.

There are many advantages of using fast EDM drilling versus conventional drilling:

- Some materials are too hard to drill using conventional methods. The EDM machine drills through almost any conductive material including carbide and hardened steel.

- Drills tend to bend in contact with the surfaces. To prevent this, additional fixtures and guide bushings must be used. With EDM drilling, the electrode never contacts the material being cut, thus eliminating the tool pressure normally experienced when drilling on curved or angled surfaces.

- Deburring holes drilled by conventional methods can take longer than the drilling. EDM drilling creates no burrs. This burr-free drilling saves time and labor and is especially crucial when difficult holes are being drilled. In addition, surface finishes are better. The smaller the hole, the more important a smooth surface is.

- Drilling holes with conventional methods is often extremely difficult if not impossible. EDM drilling is often the only practical method for producing such holes.

- As conventional drills enter or exit, they can break if torque is not carefully controlled. Small broken drills are often difficult to remove from the work piece, and time is wasted replacing broken drills and parts may have to be scrapped. With EDM drilling, torque conditions do not exist since the electrode never contacts the workpiece.

If required close tolerance, small holes EDM drilling is "the" technology to utilize. By reducing the discharge energy, holes can be polished.

This machine can be used not only to drill precise holes in medical and dental instruments, but its applications has such a wide variety and even includes drilling holes in rocket turbine blades, fuel injectors, cutting tool coolant holes, hardened punch ejector holes, plastic mold ventholes, and starter holes for wire EDM.

Waterjet high pressure coolant pump

The use of our pneumatic intensifier pump results in drilling parts up to 50% faster and with lower operating costs as much as 40%!

Our high-pressure pump produces 30% more pressure than a standard water jet pressure pump, resulting in a 40-50% increase in productivity for many materials.

Compared to a water jet pump, typical operating pressures uses 30% less water, 30% less power, and up to 50% less electrode consumption, resulting in a 40% reduction in operating costs.

Our digital generator keeps the consumption of enrgy under control and not using special oils or dielectrcal fluids keep the enviroment clean.

Being green with energy and enviroment does not only spare the nature but also your wallet.

EDM Hole Drilling - Hole Drilling EDM - EDM drilling machines

High-Speed EDM Hole Drilling - Start Hole Drilling