We can reach following savings with our novicut-M Series

-40%

-40%

Cost Reduction

Reduce your cost per part drastically

+20%

+20%

Faster cutting speed

Achieve the highest productivity with our latest-generation Zirconium guiding wheels.

-70%

-70%

Running costs

Reduce your running costs with our Molybdenum Technology

- 90%

-90%

Cutting Wire cost

Significantly reduce the highest cost-intensive influence on running costs, thanks to newest Molybdenum optimized technologies.

Novicut-M series

Lowest running costs in the market

With the Novick NOVICUT M-II wire cut series you are able to process all the conductive objects, such as complex shape moulds, cam wheels, ship machinery parts, automobile parts, aircraft parts, gears,high precision plate work and all difficult to process tough objects. You can cut plane, bevel, and the top and bottom different shaped work pieces with a maximum size of 1300 x 900 mm and till an astonishing height of 500 mm Our NOVICUT M Wire cut machine is of high performance and low cost, and leads the industry in Molybdenum wire cutting machines.

- Lowest running costs in the market

- High performance

- Taper cutting possible

- Max. cutting speed : 300 mm2 / min on Steel

- Surface finish : <=0.8 µm Ra (with multi-pass)

- Reciprocating Molydenum wire = reusable wire

- High-grade industrial CNC control system, industrial grade LCD display, HF series control software, specially developed non-resistance driving power supply and high sensitive ultra-precision micro discharge power supply.

- Full-featured, reliable stable performance, simple operation will enable beginners to bring into play 80% of the machine performance within some hours, ensure to achieve cutting effect of low speed wire cutting EDM machine.

- Fuzzy logic technology system, increases the productivity with 30%.

The price of a wire EDM machine is nothing compared to the cost of wire over the life of the machine.

“Wire is the single highest expense in operating a wire EDM.

One of the highest operating costs for any wire EDM is the cost of the wire the machine consumes during a cut. Although wire consumption rarely appears as a topic of concern for most wire EDM users, the financial benefits of owning a Molybdenum wire-cutting machine can be critical to a manufacturer’s bottom line.

EDM brass/copper wire, at its current cost of approximately 10-15 Euro a kilo, is the single highest cost related to the use of WEDM technology. The faster a machine unspools wire, the more it costs to operate that machine.

On average, most Copper/brass WEDMs unspool wire at a rate of 750 grams to 1.1 kg per hour. And although these higher rates can be reduced by slowing the unspool speed, manufacturers must then deal with increased breakage of the wire with additional adverse effects to speed, accuracy and surface finish. Under these unreliable conditions, increased cycle times and maintenance can oftentimes negate or even surpass the cost saving of slower wire feeds.

Cutting this high operating cost by 40 percent to 50 percent equates to an EDM wire saving value of about 8000€ to 10000€ per machine, per shift, per year! However, if this cost saving in consumables is offset by high maintenance costs and lost production time, there is no advantage. The ability to improve EDM wire saving while increasing productivity through reliability can have a significant impact on overall profit.

Investing in a Novicut M wire EDM will allow you to regain control over your EDM department and generate good profit. When you are facing extended lead-times and part inconsistencies due to outsourcing and the unreliability of your older machines, then it’s urgent time to think on an investment that run unattended throughout the day, over nights and even weekends. We can ensure that quality will be again to your standards and saving money hand over fist on operational costs will be again in reach.

Although wire consumption rarely appears as a topic of concern for most wire EDM users, the financial benefits of owning a low-wire-consumption machine can be critical to a manufacturer’s bottom line. With the revolutionary Molybdenium wire cutting system with zirconium guiding wheels, you will be able to have savings of up to 70 percent in many applications while maintaining precision and surface quality (Ra<0.8µ).

Because Novick builds mechanical accuracy into these machines, the on-board computers are required to perform axis movement error compensations less frequently. This allows the control to address higher priorities, like activating Novick patented Fuzzy logic technology and performing the multitude of calculations required for it to work properly.

EDM wire, at its current cost of approximately €12-15 a kg, is the single highest cost related to the use of WEDM technology. The faster a normal machine unspools wire, the more it costs to operate that machine. For shops that run a WEDM for 2000 hours per year, or one full shift, settings can experience about €0000€ each year in EDM wire saving per machine.

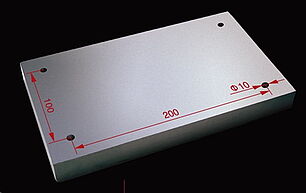

How precise is our Molybdenum wire cutting machine?

Verify yourself the precision of our molybdenum wire cutting machine

Novicut M 650-II

Precision and accuracy wire cut test

Executed: 2017-november

Material: D2 Tool Steel | 1.2379 | X153CrMo12 | SKD11

Cold Works D2 tool steel is a high carbon, high chromium tool steel (12% chrome) with extremely high wear resisting properties, heat treatable to 60-62 Rc

Electrode : Wire of 0.18mm, Molybdenium wire 99.8%

With the new advanced and patented pulse power eco generator specific for molybdenum we get much lower loss of wire (electrode wear). The diameter of a 0.18 mm wire, reduced with 0,007mm in 200.000 mm2 cutting (5 shifts of 8 hour working). This keeps the precision of the each cut at the lowest cost available!

Results :

- Average Surface roughness : Ra = 0.76 µm

- Pitch accuracy : 14µm

- Shape accuracy : 9 µm

Procedure

- Multi-cutting function 4 cuts

- Best roughness Ra < 0.68 µm

- Worst Roughness Ra < 0.78 µm

- Max. cutting speed hit 315mm2/min at highest wire speed at first cut.

Cutting with reusable Molybdenium wire

High precision with huge savings

In Europe and USA are 98% of all sold wire EDM machines based on cupper/brass wire. In Asia, more than 60 % of the machines sold till now are based on the principle of reciprocating molybenium wire principe (jig-saw movement). The wire cost of our Novicut-M-II range is till 70% lower as a standard Cu/brass wire cutting machine.

Proven technology of reusable molybdenum wire brought to the precision standards of today. With the design of the new wire-guides and the patented zirconium drive wheels, Novick succeeded to reach with a machine of half price of the copper/brass wire cutting machines, the level that is suitable for 98% of all parts: Ra<= 0.8µm and precision of +- 4µm

The new generator of the Novicut-M II, in combination with the new patented guiding system, and supported by the 4 step wire speed, has improved drastically the precision and the surface quality of the finished parts and this with a speed increase of around 40%.

With the Novicut 350M-II, you reach already a better surface roughness than Ra 1.0µm after three-cuts.

Cuts times | Efficiency in mm²/min | Roughness Ra in µm | Efficiency in mm³/min | Roughness Ra in µm |

1 | 115-145 |

| 90-100 |

|

2 | 80-90 | 1.5-1.7 | 60-70 | 1.9-2.2 |

3 | 55-65 | 0.8-1.0 | 50-56 | 1.2-1.6 |

4 | 50-54 | 0.7-0.9 | 45-50 | 1.0 |

Specifications novicut M-II

Molybdenum Wire cutting Machines with Zirconium guiding wheels.

| Main machine | 650M-II | 800M-II | 1000M-II | 350M-II see new 400M-III | 450M-II see NEW 500M-III | |

|---|---|---|---|---|---|---|

| Size of machine | mm | 2340x2025x2580 | 2590x2400x2610 | 2860x2653x2620 | ||

| Weight of machine | kg | 3000 | 3500 | 4000 | ||

| Size of worktable | mm | 920x620 | 1100x800 | 1300x900 | ||

| Travels(X/Y/U/V) | mm | 650x500x36x36 | 800x630x36x36 | 1000x800x36x36 | ||

| Travels Z | mm | 450 motorized | 500 motorized | 500 motorized | ||

| Max.Cutting taper without closed wire guide | ° | ±6°/50mm | ±6°/50mm | ±6°/50mm | ||

| Max.Cutting taper with closed wire guide | ° | ±10°/80mm | ±10°/80mm | ±10°/80mm | ||

| Size of work tank - Internal effective size | mm | 1300x800 | 1500x1000 | 1660x1100 | ||

| Max.Cutting thickness | mm | 500 | 500 | 500 | ||

| Wire-driving structure | ||||||

| Wire tighten | Automatically | Automatically | Automatically | |||

| Wire loading | Semi-auto/manual | Semi-auto/manual | Semi-auto/manual | |||

| Tension control of wire | Constant tension | Constant tension | Constant tension | |||

| Workpiece | ||||||

| Max.Workpiece weight | kg | 1200 | 1500 | 1500 | ||

| Max.Workpiece size | mm | 1100x800x500 | 1300x800x500 | 1300x900x500 | ||

| Power supply system | ||||||

| Strandard configuration | v | 380V±10%/50HZ 2KVA | 380V±10%/50HZ 2KVA | 380V±10%/50HZ 2KVA | ||

| Generator and machining technology | ||||||

| Max.Machining current | A | 15 | 15 | 15 | ||

| Max.cutting speed | mm²/min | >300 | >300 | >300 | ||

| Best roughness | μm | Ra≤0.8 | Ra≤0.8 | Ra≤0.8 | ||

| Standard technology parameters | Steel/copper/ aluminium/carbide | Steel/copper/ aluminium/carbide | Steel/copper/ aluminium/carbide | |||

| CNC control system | ||||||

| Equipment | Industrial PC/SSD/Color LED display/FeRAM memory | Industrial PC/SSD/Color LED display/FeRAM memory | Industrial PC/SSD/Color LED display/FeRAM memory | |||

| Connection | USB&LAN interface | USB&LAN interface | USB&LAN interface | |||

| Keyboard | Water proof stainless keyboard | Water proof stainless keyboard | Water proof stainless keyboard | |||

| Programmable axes | XYUV 4 axes(controlled simultaneously) ( optional : A axes ) | XYUV 4 axes(controlled simultaneously) ( optional : A axes ) | XYUV 4 axes(controlled simultaneously) ( optional : A axes ) | |||

| Program mode | Novick CAD/CAM/ISO | Novick CAD/CAM/ISO | Novick CAD/CAM/ISO | |||

| Servo type | XY DC servo ( Optional : AC servo ) | XY DC servo ( Optional : AC servo ) | XY AC servo | |||

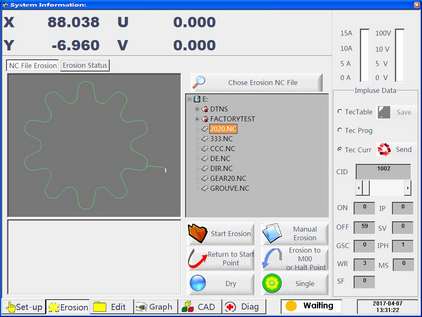

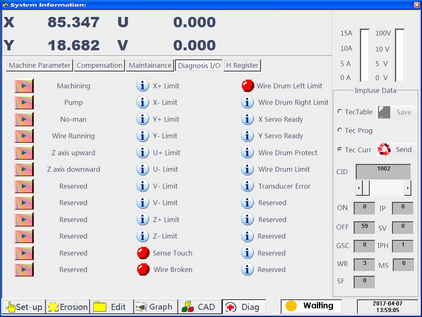

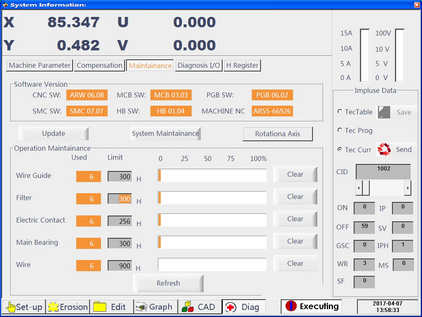

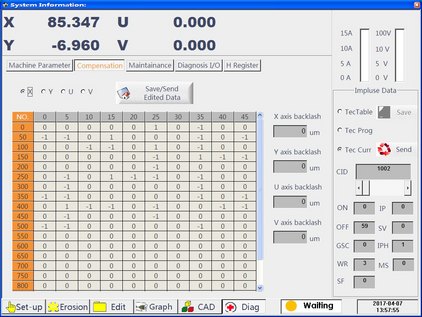

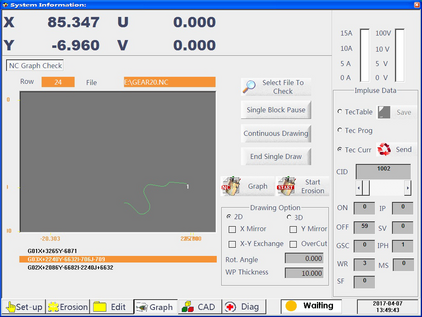

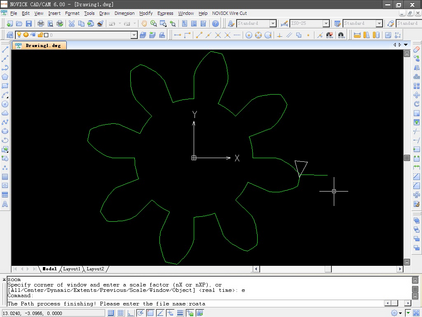

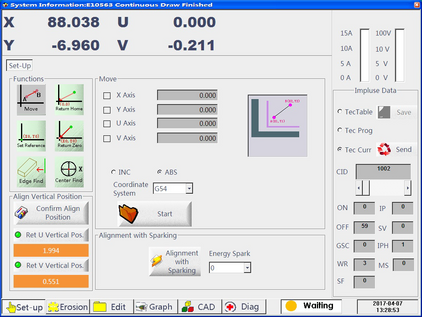

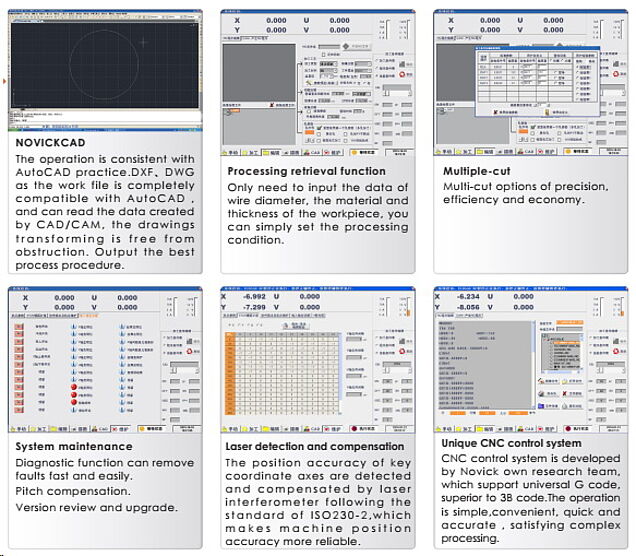

Controller including Cad

Novick CAD software system brings you a user-friendly experience

-

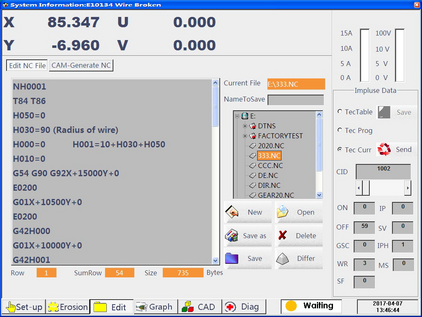

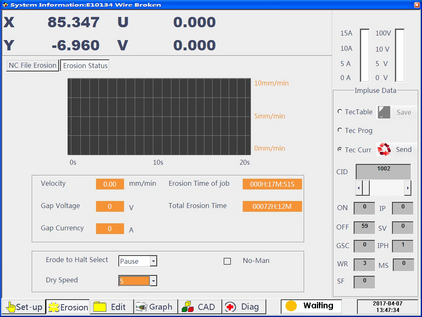

6 pages of screens, consisted of Manual, Erosion, Edit, Graph, Diagnostic, CAD/CAM offer very friendly man-machine interface

-

Real-timely multi-tasking control software makes it possible to do preparations for next jobs during erosion.

-

The friendly man-machine interface can meet the needs both for beginners and experienced operators.

-

NC programming takes the standard ISO G/M code .

-

Integrated CAD/CAM programming system allows operators to design NC programs automatically by key-in drawings in machine or receiving drawing files in DXF format from serial communication interfaces.

-

With powerful CNC function, edge Find,Center Find, Automatically.

-

With USB interface and LAN communication interface, the machine can exchange datum with programming computers or control center conveniently.

Download here your latest Catalogue of this machine! (copy 1)

Novick Catalogue download

Catalogue Novicut M

High Speed wire cutting