Novidrill PRO Plus Range

4 models full CNC EDM drilling Machines

| Model | Novidrill 400Pro+ | Novidrill 500Pro+ | Novidrill 630Pro+ | Novidrill 800Pro+ | |

|---|---|---|---|---|---|

| Table dimensions | mm | 420 x 620 | 500 x 700 | 685 x 1020 | 750 x 1150 |

| X-Y stroke | mm | 300 x 400 | 400 x 500 | 500 x 630 | 600 x 800 |

| Z1 Stroke - Electrode drilling stroke | mm | 350 | 350 | 400 | 500 |

| W Stroke - electrode guide stroke | mm | 160 | 160 | 160 | 160 |

| Z2 Stroke - Spindle head stroke | mm | 260 | 260 | 260 | 260 |

| Highest workpiece possible | mm | 420 | 420 | 500 | 600 |

| Drilling Capacity | mm | 0.2-6 | 0.2-6 | 0.2-6 | 0.2-6 |

| Drilling Generator | A | 50 | 50 | 50 | 50 |

NOVIDRILL PRO +

Full range of Affordable CNC EDM Drilling Machines

Model Novidrill 400 Pro+

Hole drilling EDM

Our Novidrill EDM Rapid hole drilling machines use low cost electrode tube (normally brass or copper material) to drill holes on a electrically conductive material at a very high speed, the hole depth diameter ratio can reach up to 300. The hole diameter is normally from 0.3mm to 3.0mm, the machine can drill holes on a inclined surface workpiece. This technology is widely used for hole machinig in aerospace, energy, cutting tools, automotive, medical, mold and die industries.

High-speed EDM hole drilling was designed especially for fast, accurate small- and deep-hole drilling applications. Small holes that were once almost impossible to drill by conventional machine tools are now being performed with ease. With the capability of drilling through virtually any conductive material, the use of this technology is continually expanding.

Considered a last resort for drilling holes, Fast Hole EDM Drilling (Electrical Discharge Machining) is quickly becoming the standard method for producing small, tight tolerance holes. It is an extremely cost effective method for producing fast and accurate holes into all sorts of whether hard or soft conductive materials.

NOVIDRILL PRO PLUS : CNC EDM DRILLING MACHINES

Affordable and good cnc EDM drilling : 3 - 4 - 5 axis cnc control

Novidrill PRO plus

High End CNC EDM controller

The Novidrill embedded high-end CNC system have been widely applied to machine tool and other manufacturing industries. Customized development was carried out according to Novidrill's demands and it’s of high flexibility.

The Novidrill's CNC Controller is an embedded intelligent control system with independent core technology, and is the key product researched and developed successfully for the purpose of breaking foreign countries’ monopoly in high-end control technology.

Novidrill series network-based CNC system: the product is the core product researched and developed successfully by the company on the basis of CNC system software & hardware platform of Ethernet communication technology of completely proprietary intellectual property rights.

The main technical indexes include:

1) 5 control shafts + main shaft, 5-shaft linkage;

2) Minimum moving unit: 0.001mm, maximum speed: 30m/min;

3) Radius, length, abrasion and reverse gap compensation of the tool;

4) High-speed & high-precision 3D dynamic front contouring control;

5) Rapid graphic simulation display and real-time 3D trajectory dynamic graphic processing analog display;

6) Break-point memory processing and power-off protection function;

7) It’s able to designate to start processing from any line;

8) Interface signal: 32I/24O;

9) It can extend to 196I/196O through CAN bus;

10) It supports the input of documents in DXF format directly.

Granite Table Standard

Big advantages:

Can not drill in the table

Table resist to corrosion of the dielectricum (drilling liquid)

Don't get rusty

Keeps the super precision in time and guarantees a better flatness

Parts can not be welded to the table due to electrical current thruth contact surface with table

CAN USE NORMAL TAP-WATER

More economical is not possible.

Designed to meet the needs of any job shop and the most demanding Toolmaking workshop, the Novidrill PRO-plus is simply the most unique EDM Drill on the market today. This feature packed machine combines affordability, precision and versatility with a host of standard features.

Compare the features with others and we are sure you’ll agree: The Novidrill PRO-plus offers more than competitive machines that sell for twice the price!

Novidrill‘s ability to use ordinary tap water as dielectric, coupled with a unique super high pressure pump system which provides excellent flush and stability at the electrode during the burn.

An EDM drilling system simply must get the job done – and must not distract from important tasks. The Novidrill PRO+ is therefore designed to bring the user quickly and simply to his goal. Speed and simplicity are also all-important as far as maintenance and organization are concerned – everything is readily accessible and accommodated immediately in the machine.

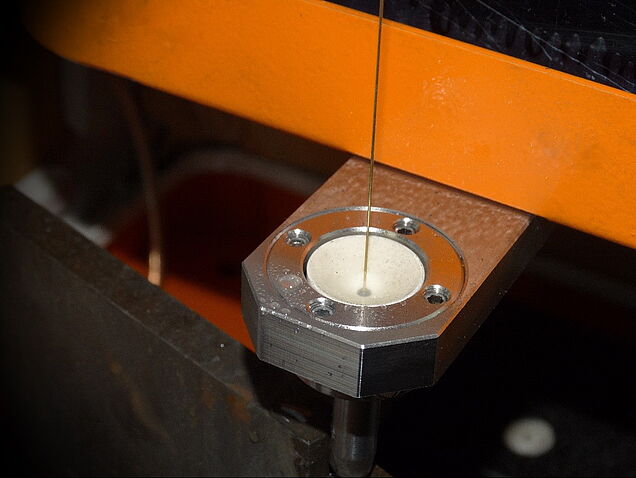

The perfect complement to the wire-cutting machines. The start-EDM drilling systems not only master small dimensions on start holes with 0,3–3,0 mm electrodes, but also functional bores.

High Speed drilling with reduced bullet nosing

High pressure pump 120 Bar max

- Novidrill-II uses a unique pneumatic activated high pressure (70 – 120 bar) coolant/dielectric/water pump. The combination of the super high-pressure dielectric fluid, the rotation of the tubular electrode and the high electrode feed rate (controlled by a fast response servo) make it possible to produce holes at a very fast rate and of very small dimensions (till 0,2mm diameter)

- High pressure dielectric fluid is one of the most important factors, which is usually supplied to the gap through the bore of tubular electrodes.

- The use of our pneumatic intensifier pump results in drilling parts up to 50% faster and with lower operating costs as much as 40%! Our high-pressure pump produces 30% more pressure than a standard water jet pressure pump, resulting in a 40-50% increase in productivity for many materials. Compared to a water jet pump, typical operating pressures uses 30% less water, 30% less power, and up to 50% less electrode consumption, resulting in a 40% reduction in operating costs. Being green with energy does not only spare the nature but also your wallet.

- Auxiliary Flush provides continuous cleaning of die guide and work piece and aids electrode entry and breakthrough.

- peed and simplicity

- Drilling rates up to 1mm/second can be achieved and obtainable hole sizes are between 0.2 and 3mm, with a length-to-diameter ratio of over 300:1. The process can be applied in the production of a variety of parts including fuel injectors, cutting tools, medical equipment, start holes for wire cut and more.

- Factors including the generator (electrical parameters), electrode geometry and most important, the dielectric flushing are very important for the correct EDM process. Drilling time and electrode wear can be reduced by 85 % and 45% respectively, depending on the type of electrode geometry used and pressure of coolant applied.

The new developed High Performance generator of the Novidrill allows machining of all steel and Tungsten Carbide materials.

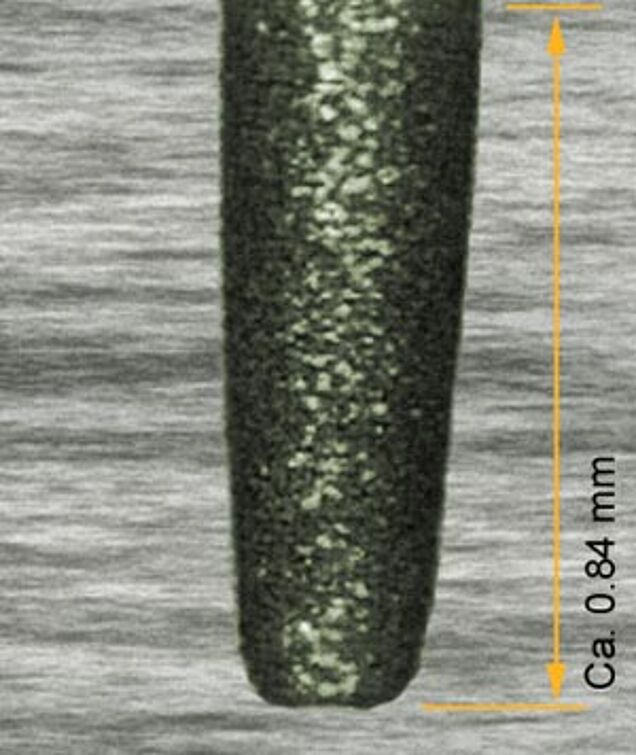

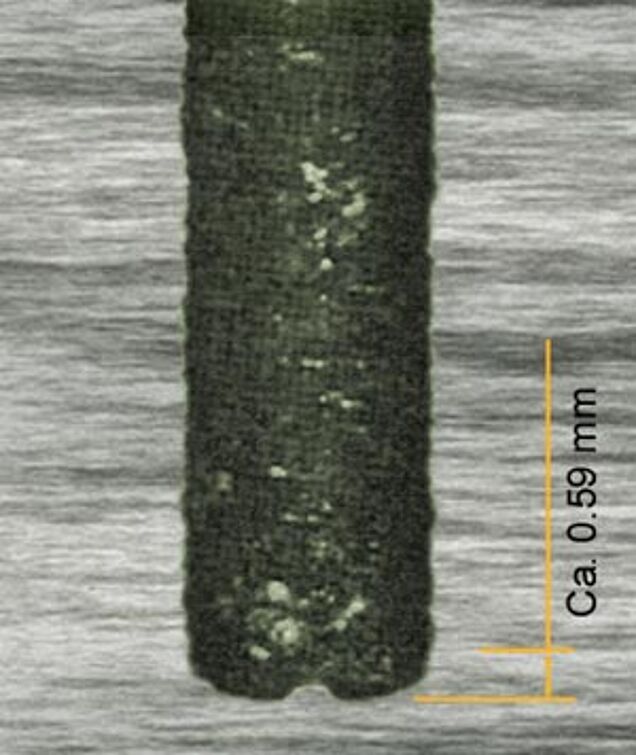

The Electrode wear is virtually all on the bottom of the electrode (not on the side like on machines with conventional generator), which avoids conic wear. As a result, the breach has a perfect shape and will be reached much faster!

Today’s most economical solution for producing high precision and high-speed holes.

Electrical Discharge Hole Drilling (EDHD) - EDM-drilling

Considered a last resort for drilling holes, Fast Hole Electrical Discharge Machining (EDM) Drilling is quickly becoming the standard method for producing small, tight tolerance holes. It is an extremely cost-effective method for producing fast and accurate holes into all sorts of whether hard or soft conductive materials. EDM drilling operates on the principal of eroding material via the use of electric energy.

There are many advantages of using fast EDM drilling versus conventional drilling:

- Some materials are too hard to drill using conventional methods. The EDM machine drills through almost any conductive material including carbide and hardened steel.

- Drills tend to bend in contact with the surfaces. To prevent this, additional fixtures and guide bushings must be used. With EDM drilling, the electrode never contacts the material being cut, thus eliminating the tool pressure normally experienced when drilling on curved or angled surfaces.

- Deburring holes drilled by conventional methods can take longer than the drilling. EDM drilling creates no burrs. This burr-free drilling saves time and labor and is especially crucial when difficult holes are being drilled. In addition, surface finishes are better. The smaller the hole, the more important a smooth surface is.

- Drilling holes with conventional methods is often extremely difficult if not impossible. EDM drilling is often the only practical method for producing such holes.

- As conventional drills enter or exit, they can break if torque is not carefully controlled. Small broken drills are often difficult to remove from the work piece, and time is wasted replacing broken drills and parts may have to be scrapped. With EDM drilling, torque conditions do not exist since the electrode never contacts the workpiece.

If required close tolerance, small holes EDM drilling is "the" technology to utilize. By reducing the discharge energy, holes can be polished.

This machine can be used not only to drill precise holes in medical and dental instruments, but its applications has such a wide variety and even includes drilling holes in rocket turbine blades, fuel injectors, cutting tool coolant holes, hardened punch ejector holes, plastic mold ventholes, and starter holes for wire EDM.

MAIN FEATURES:

• Compact space-saving design with integral dielectric system and generator for machining of small and medium-size parts

• Machine casting frame uses high quality cast iron, heat treated for stress release to keep machine body high rigidity without deformation.

• Machine construction according to computer analysis of tensile strength, compression resistance and stiffness strain.

• Highly accurate spindle head with the quill running on pre-loaded cross roller bearings

• Servo drive - step motor on Z axis for reliable control

• Manual central lubrication for table guides and spindles

• User-friendly, easy to learn operation; parameters are entered directly in the control panel and can be easily optimized.

Drilling times samples

Drilling times depend on the hole size and type of material. A few examples.

| Material | Electrode Dia. | Drill Depth | Machining Time |

| Alloy Tool Steel | 0,5mm | 12,5mm | 25 ~ 35 seconds |

| 0,5mm | 25mm | 50 ~ 60 seconds | |

| 1,0mm | 25mm | 55 ~ 65 seconds | |

| Tungsten Carbide | 0,5mm | 12,5mm | 4 ~ 5 minutes |

| 0,5mm | 25mm | 8 ~ 9 minutes | |

| Aluminum | 0,5mm | 12,5mm | 40 ~ 50 seconds |

| 0,5mm | 25mm | 90 ~ 100 seconds | |

| 1mm | 70mm | 3 minutes |

Drilling of 0.2 mm hole in mold steel

At customer workshop.

High Precision drilling guides

Easy changing of drilling diameterdiameter

MAIN ADVANTAGES:

- Accommodates 0.2 mm to 4.0 mm diameter electrodes (optional 6~8 mm with bigger generator)

- Electrodes up to 400/500 mm length

- High speed processing generator

- High precision Guide for super precision drill positioning

- High precision on all three axes for accuracy and user-friendly operation with 0,001 mm smallest input value

- Operator friendly swivel control panel

- Coordinate auto calculate for drilling on circle or angular line

- Best high-pressure coolant pump on the market

- Standalone high capacity filtration unit with 5-Micron coolant Filtration System

- Splash Guards

- Power W Axis provides easy adjustment to accommodate a maximum 400/500mm work piece height

- Novidrill PRO+ models can use ordinary tap water as dielectric. This coupled with a high-pressure air pump system to provide for excellent flush and stability at the electrode during the burn makes the set-up operation more user friendly while keeping work free of oils or other contaminates.

- Solid design of the machine base. The meehanite cast iron components and high-grade guides are an assurance of durability and long-term accuracy.

- Good accessibility permits convenient and swift set-up. The tidy work area is designed and optimized for easy workpiece clamping. Furthermore, the work table from granite makes the machine compact and permits loading with heavier workpieces.

- Drilling rates up to 1mm/second can be achieved and obtainable hole sizes are between 0.2 and 3mm, with a length-to-diameter ratio of over 150:1. The process can be applied in the production of a variety of parts including fuel injectors, cutting tools, medical equipment, start holes for wire cut and more.

- This makes set up and operation more user friendly and keeps work free of oils or other contaminates. The user-friendly control allows simple input of cutting variables. Included is an audible edge find, voltmeter to monitor stableness of burn and Programmable Digital Readout for ease of positioning. A standard feature is a Power Back Slide (W Axis) for additional travel to accommodate increased part thickness.

- Novidrill PRO+ not only manages small dimensions on start holes with 0,2– 3,0 mm electrodes, but also functional bores. It offers comfortable operation during automatic positioning, while the CNC can calculate automatic many hole coordinates.

The use of our pneumatic intensifier pump results in drilling parts up to 50% faster and with lower operating costs as much as 40%!

Our high-pressure pump produces 30% more pressure than a standard water jet pressure pump, resulting in a 40-50% increase in productivity for many materials.

Compared to a water jet pump, typical operating pressures uses 30% less water, 30% less power, and up to 50% less electrode consumption, resulting in a 40% reduction in operating costs.

Our digital generator keeps the consumption of enrgy under control and not using special oils or dielectrcal fluids keep the enviroment clean.

Being green with energy and enviroment does not only spare the nature but also your wallet.

Download here your latest Catalogue of this machine!

Novick Catalogue download

Catalogue Novidrill 3th Generation Pro+

CNC EDM Drilling Without Limits

Visit also our specific EDM Drilling website: www.novidrill.eu

New special EDM Drilling website: www.novidrill.eu

Rapid EDM drilling machine,Novidrill, Hole drilling EDM, cnc edm drill, edm popper, Manual EDM Drills, high speed EDM drilling machine ,Start Hole drilling machine, EDM Drilling machine, Deep hole drilling machine, Fine Hole machine, Fine Hole, EDM DrillMate, EdmDrill, EdmDrill TM, SMALL HOLE EDM DRILLING, Start Hole Drilling, HIGH PRECISION HOLE POPPERS, Small Hole EDM, low cost edm drilling, low cost edm drilling machine, low cost deep hole drilling , novidrill, novick drilling machine, high speed drilling machine, small hole drilling machine, deep hole drilling machine, small hole EDM, small hole EDM machines, small hole EDM machines, micro hole drilling, miicro hole drill. micro hole drilling machine