NOVICUT : Wire-cutting made affordable

Novicut®: Reduce your wire cutting cost.

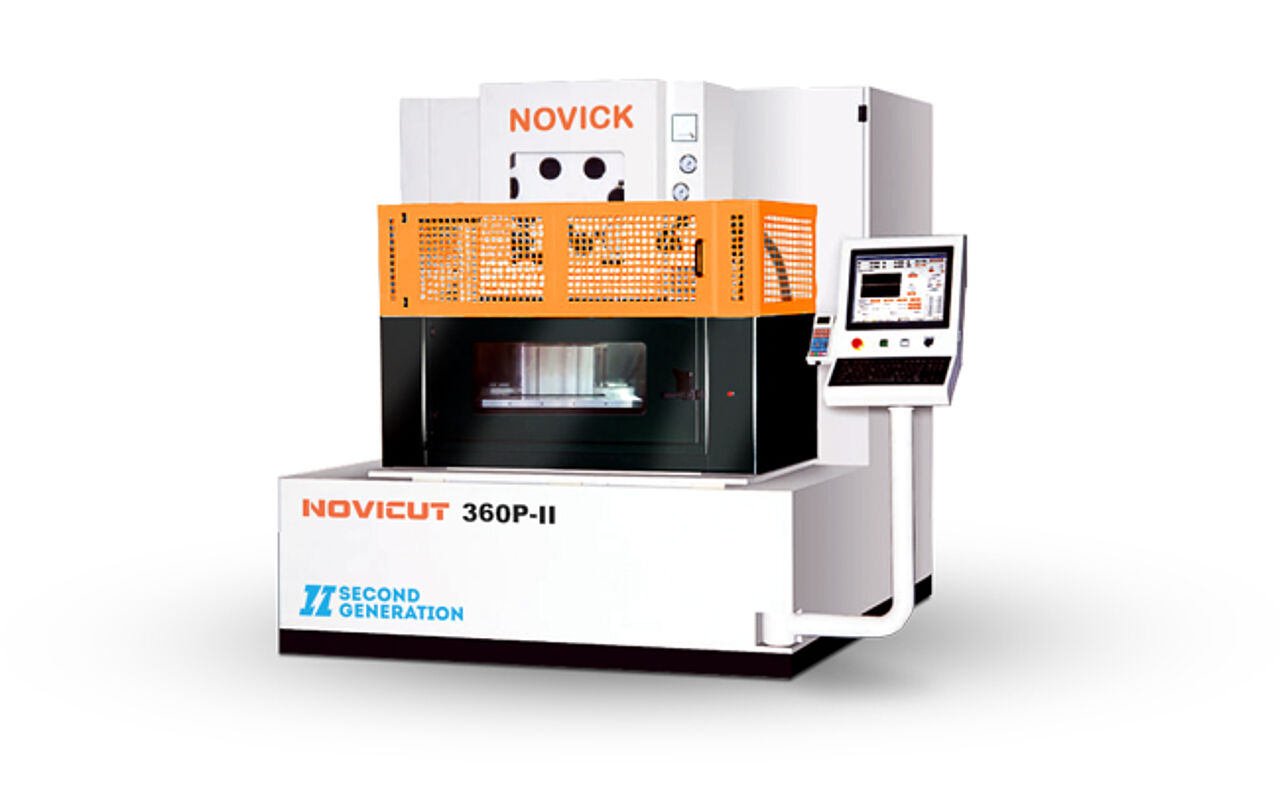

NOVICUT-P360-II - Precision is all that matters

Highest precision at an affordable price

Novicut P360-II

The Noviform-P360-II offers a high level of flexibility and low running cost, the ideal machines for any EDM work shop.

The new, modern machine design creates homogeneity with the entire Novick product range.

Novicut® P Series offers you a broad range of 2 die sinking machines of different table sizes. What they both have in common is high precision, reliability and affordable prices: all valuable characteristics the machines owe to our well proven and highly advanced technology.

All Novicut®-P machines are built around a proven heavily ribbed cast iron frame, delivering mechanical stability and precision for the lifetime of the machine, regardless the work piece weight or the dielectric volume

NOVICUT P500-II - High Precison Wire cutting

Highest precision at an affordable price

Novicut P500-II

The Noviform-P500-II offers a high level of flexibility and low running cost, the ideal machines for any EDM work shop.

The new, modern machine design creates homogeneity with the entire Novick product range.

Novicut® P - Precision-Series offers you a broad range of 2 die sinking machines of different table sizes. What they both have in common is high precision, reliability and affordable prices: all valuable characteristics the machines owe to our well proven and highly advanced technology.

All Novicut®-P machines are built around a proven heavily ribbed cast iron frame, delivering mechanical stability and precision for the lifetime of the machine, regardless the work piece weight or the dielectric volume

With AC MOSFET high speed non-electrolytic pulse power

High Quality Configuration

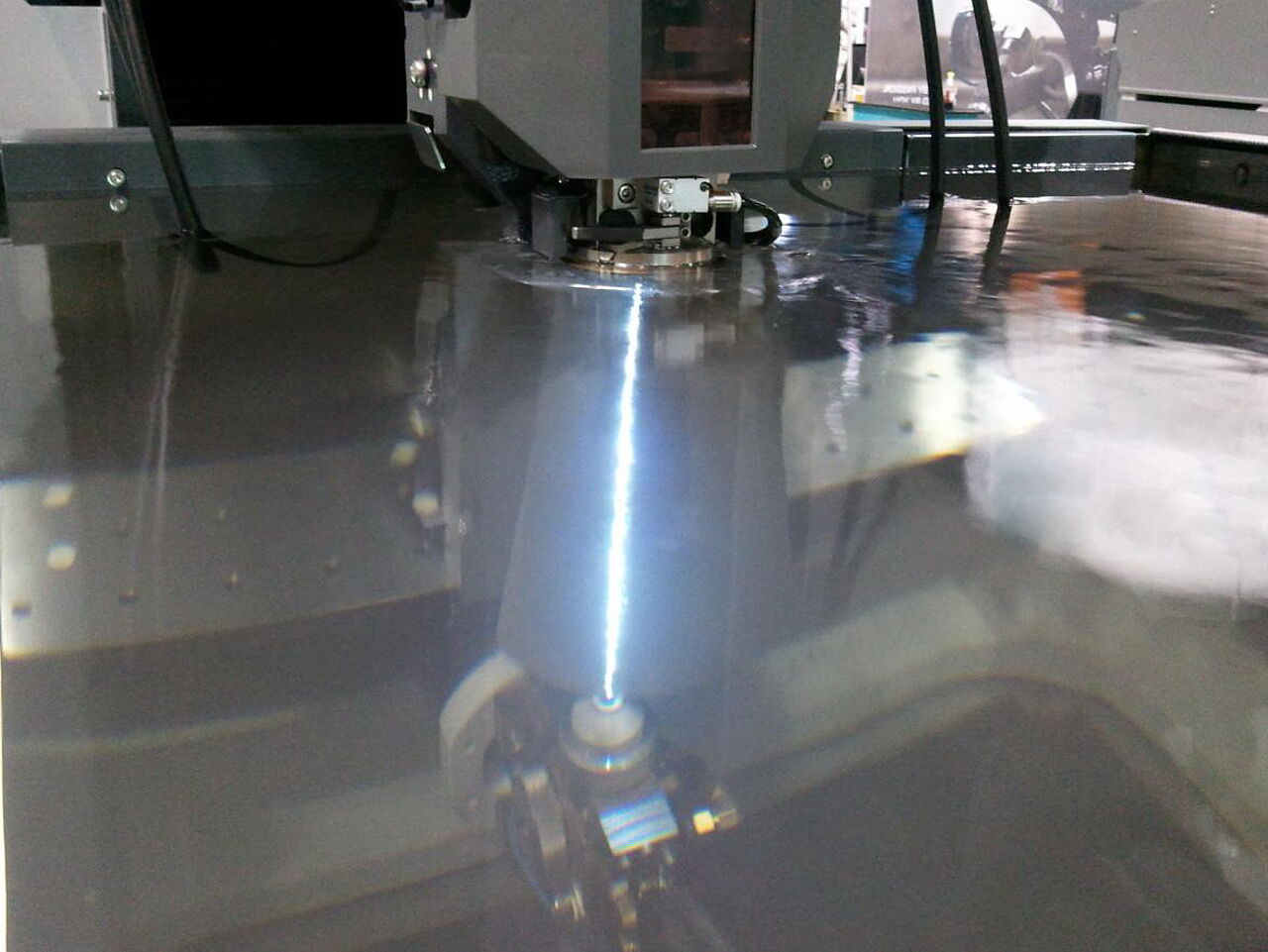

·High speed non-electrolytic pulse power with alternating polarity is adopted in our latest Generation High precision wire cutting machine. This to make the positive and negative ionsgenerated in the processing basically remain in situ, inhibit the occurrence of electrolytic corrosion, prevent the formation of softening layer, and improve the service life of the mold.

·With unique leading finishing module, a 30mm thickness workpiece’s surface roughness can be quickly machined to Ra=0.4μm or less.

·Dedicated mirror finishing power supply, the best surface roughness Ra≤0.25μm.

2nd Generation of P-Series: Super High Precision wire cutting machines

Novicut-P-II

Super Precision and high wire cut machine with continue fed copper/Brass-based wire for super high precision and high surface quality. The wire is usually made of brass or stratified copper, and is between 0.05 and 0.3 mm diameter and for single use.

Closed loop 0.5µm direct measuring scales guarantee the microscopic precision.

Equipped with High Response drives.

Novicut - P - IInd Generation - 2020

Precision - Speed - Auto rewire - Stability - Affordable

| Machine | Model | Novicut-P360-II | Novicut-P500-II |

|---|---|---|---|

| Travels X/Y/Z | mm | 360×250×210 | 500×350×300 |

| Travels U/V | mm | 100×100( with optional AWF:90×90) | 100×100( with optional AWF:90×90) |

| Max.cutting taper | °/mm | ±30°/50mm | ±30°/50mm |

| Size of work tank | mm | 910×680×260 | 1120×800×350 |

| Size of worktable | mm | 650×485 | 800×585 |

| Max.size of workpiece | mm | 900×600×210 | 1000×600×295 |

| Max.weight of workpiece | kg | 400 | 500 |

| Type of machining | Submerged/Flushing | Submerged/Flushing | |

| Diameter of closed wire guide | mm | φ0.15~φ0.30 | φ0.15~φ0.30 |

| Diameter of electrode wire | mm | 0.15/0.20/0.25/0.30 | 0.15/0.20/0.25/0.30 |

| Dimensions of wire reel | mm | Max. outside diameter φ160 | Max. outside diameter φ160 |

| Wire tension | Automatic constant tension | Automatic constant tension | |

| Wire speed | mm/s | Up to 200 | Up to 200 |

| Threading device | Optional automatic wire threading device(AWF) | Optional automatic wire threading device(AWF) | |

| Size of machine | mm | 2700×2300×2250 | 2850×2400×2250 |

| Weight of machine | kg | 3000 | 3300 |

| Generator | |||

| Max.cutting speed | mm²/min | 160(φ0.25 brass wire)/250(optional) | 160(φ0.25 brass wire)/250(optional) |

| Best roughness | μm | Ra≤0.45(0.25 optional) | Ra≤0.45(0.25 optional) |

| Work type | AC MOSFET non-electrolytic power | AC MOSFET non-electrolytic power | |

| Standard technics | Steel,carbide,copper,graphite | Steel,carbide,copper,graphite | |

| CNC control system | |||

| Control system | CPU | CPU | |

| Operation system | Windows | Windows | |

| Hardware configuration | 64G ssd,17″LCD | 64G ssd,17″LCD | |

| Input/output interface | Keyboard,USB,LAN | Keyboard,USB,LAN | |

| Axes controlled | XYUVZ axes(4 axes controlled simultaneously) | XYUVZ axes(4 axes controlled simultaneously) | |

| Memory function | With memory function | With memory function | |

| Power supply system | |||

| Standard power supply | V | 3x380V 50/60Hz | 3x380V 50/60Hz |

| Max.machining current | A | 25 | 25 |

| Power input | KVA | 7 | 7 |

The Novicut-P range puts efficiency at the touch of your finger with a smart, easy-to-use human-machine interface (HMI) and onboard technologies that streamline your job setup, improve your cutting speed, improve your surface finish, protect your valuable workpieces, and ensure your process robustness.