The PCBN inserts types and grades

PCBN inserts are being made with ceramics and metallic binders as per the requirements in terms of hardness for material removal. The ceramics binder makes the insert strongly wear resistant, especially the chemical type. The CBN content in ceramics bonded insert is generally 40 to 65%.

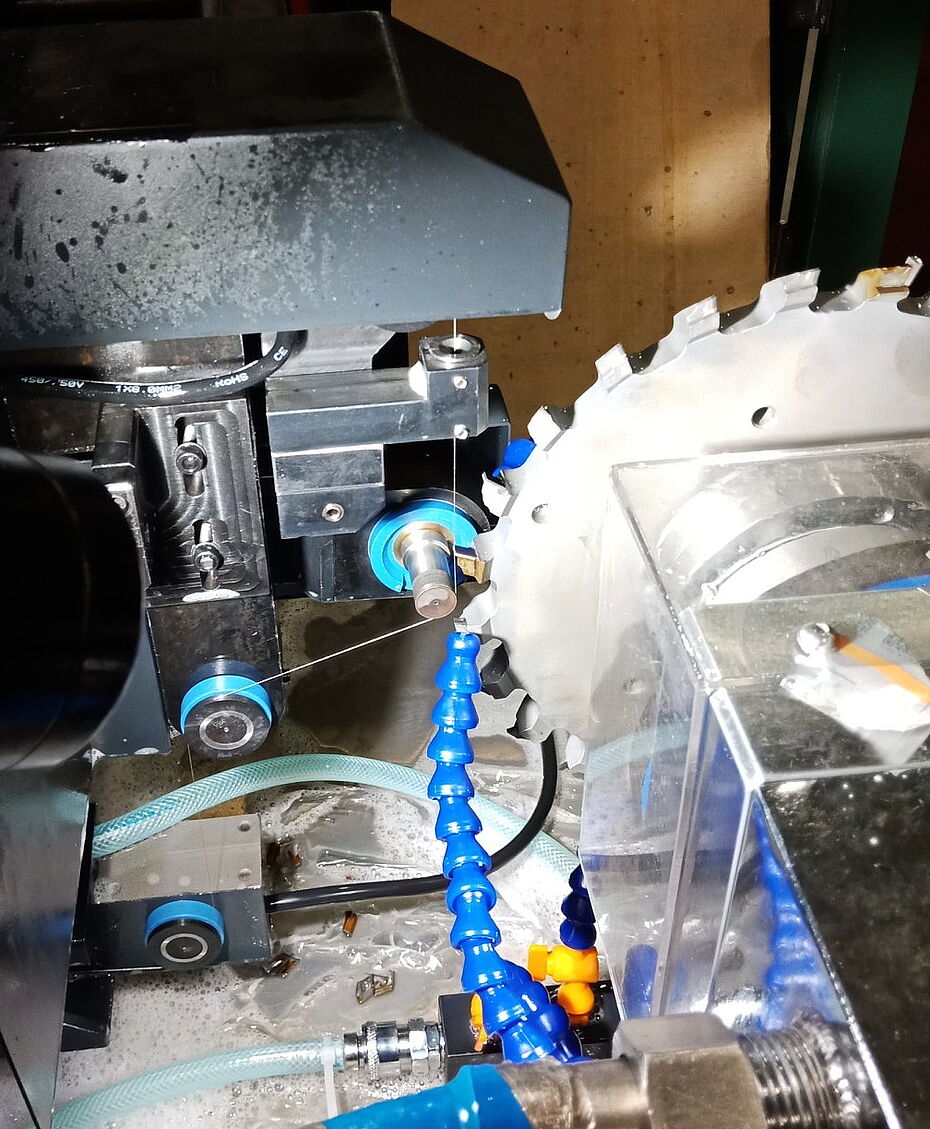

The higher CBN content like 85 to 100 % in the insert has a metallic binder which improves the toughness and wears resistance further. This metalic binder allows us to cut the inserts by Electro erosion wire cutting.

PCBN tools have developed fine demand

The demand of PCBN cutting tools is because of the heat and chemical resistance that the substance offers, and this directly corresponds to the wear resistance against diversity of substrates to be worked upon. The cubic structure-based BN (cBN) resembles the diamond and hence performs analogously to it. On the other hand, the hexagonal structure-based BN resembles graphite, is soft and thus used as a lubricant and as an additive in cosmetics. The ability to make custom components with cBN is also an essential parameter that makes PCBN products more desirable for cutting, turning, drilling & grinding tasks of diversity.

For manufacturing many types of custom grinders and polishers, the diamonds or PCD types could prove very expensive; especially in comparison to the applications in which these are to be used. Thus, the ability to make customized PCBN tools coupled with the cost advantage makes them quite popular in the enterprising applications.

Novicut M-T : PCD - PCBN - Toolmaster

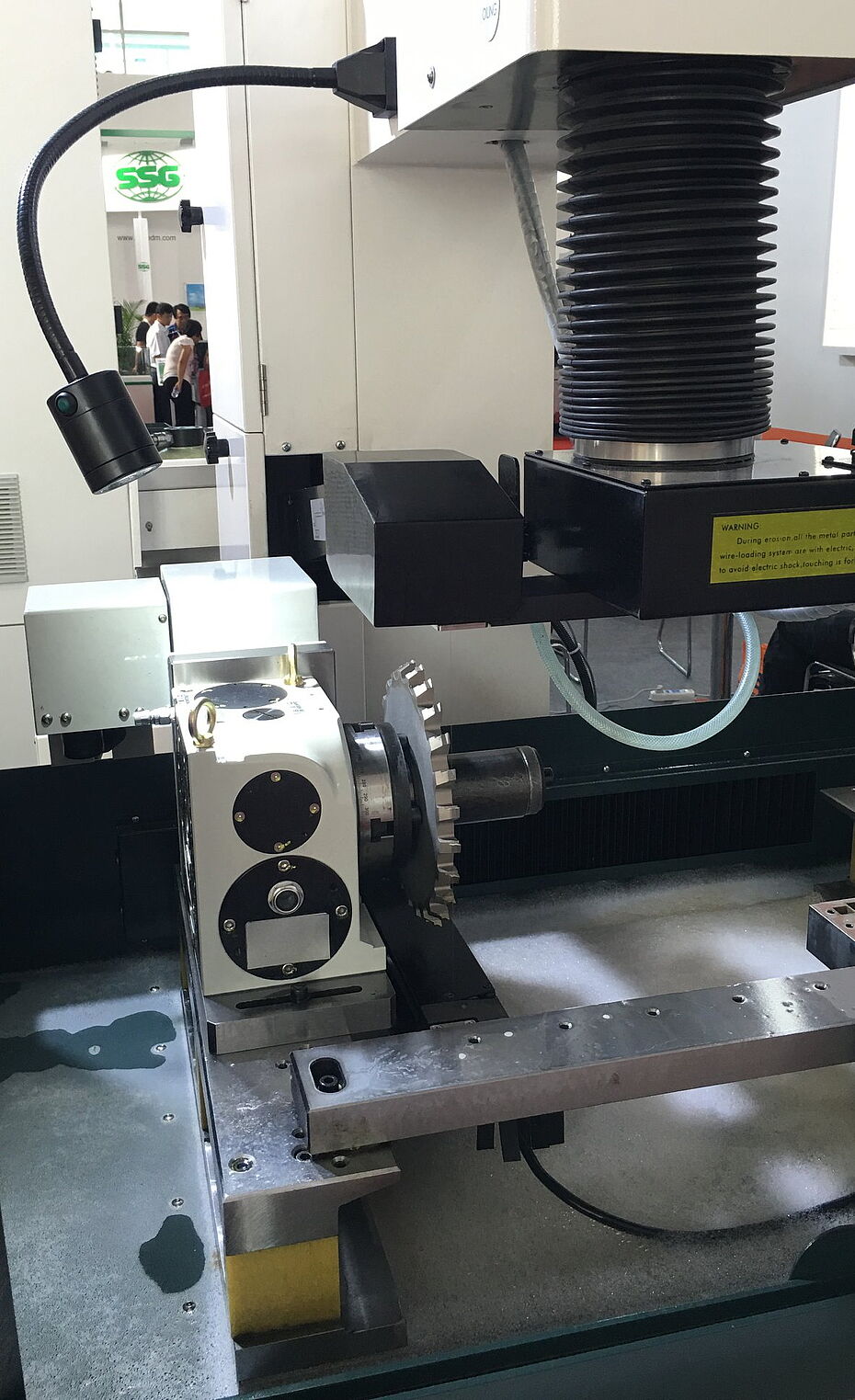

First Molydenum Wirecutting machine for PCD - PCBN material

For the first time, Novick is offering a flexible, low-cost solution for the cutting and sharpening of Polycrystalline Diamond (PCD) tools. With novick's new PCD - PCBN Package, EDM users will have everything they need to accurately cut complex tools, using our traditional EDMs and controls that they are already familiar with. Unlike many PCD - PCBN solutions, Novick includes a dedicated PCD - PCBN discharge unit capable of reducing tool chipping by as much as 70% as part of this package. The result is a high-performance, cost-effective solution with an interface already familiar to most users at a fraction of the price from others.. Creating and repairing PCD - PCBN tools has never been easier and more profitable

Controller

-

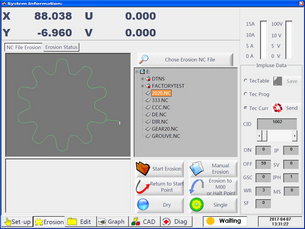

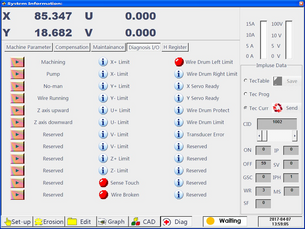

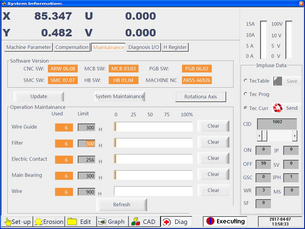

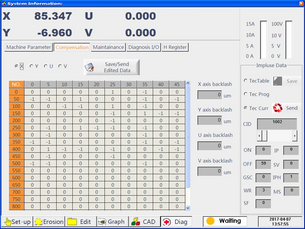

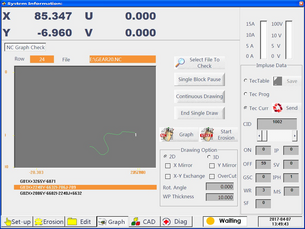

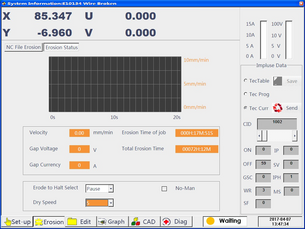

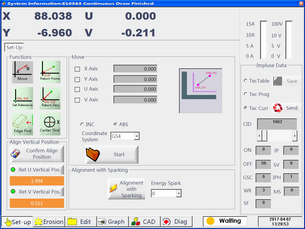

6 pages of screens, consisted of Manual, Erosion, Edit, Graph, Diagnostic, CAD/CAM offer very friendly man-machine interface

-

Real-timely multi-tasking control software makes it possible to do preparations for next jobs during erosion.

-

The friendly man-machine interface can meet the needs both for beginners and experienced operators.

-

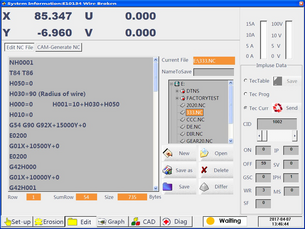

NC programming takes the standard ISO G/M code .

-

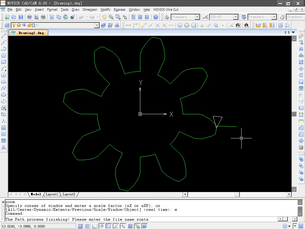

Integrated CAD/CAM programming system allows operators to design NC programs automatically by key-in drawings in machine or receiving drawing files in DXF format from serial communication interfaces.

-

With powerful CNC function, edge Find,Center Find, Automatically.

-

With USB interface and LAN communication interface, the machine can exchange datum with programming computers or control center conveniently.