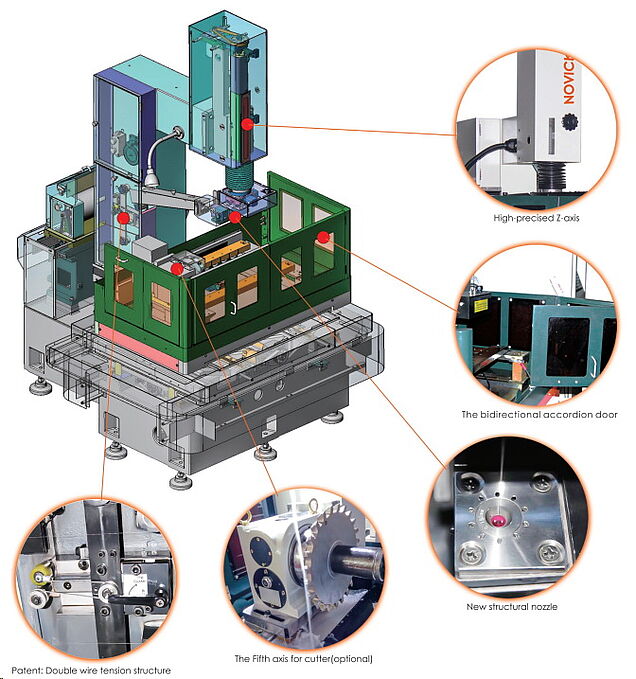

Novicut-M Series : Lowest running costs in the market

New WIDE ANGLE design +-15° with high precision

With the Novick NOVICUT M-III wire cut series you are able to process all the conductive objects, such as complex shape moulds, cam wheels, ship machinery parts, automobile parts, aircraft parts, gears,high precision plate work and all difficult to process tough objects. You can cut plane, bevel, and the top and bottom different shaped work pieces. Our NOVICUT M Wire cut machine is of high performance and low cost, and leads the industry in Molybdenum wire cutting machines.

- Lowest running costs in the market

- High performance

- Taper cutting possible

- Max. cutting speed : 300 mm2 / min on Steel

- Surface finish : <=0.8 µm Ra (with multi-pass)

- Reciprocating Molydenum wire = reusable wire

- High-grade industrial CNC control system, industrial grade LCD display, HF series control software, specially developed non-resistance driving power supply and high sensitive ultra-precision micro discharge power supply.

- Full-featured, reliable stable performance, simple operation will enable beginners to bring into play 80% of the machine performance within some hours, ensure to achieve cutting effect of low speed wire cutting EDM machine.

- Fuzzy logic technology system, increases the productivity with 30%.

How precise is our Molybdenum wire cutting machine?

Verify yourself the precision of our molybdenum wire cutting machine

| machine | Novicut-400M-III - NEW | Novicut-600M-III - (Soon available) | |

| Size of worktable | mm | 590x440 | 800x580 |

| Travels(X/Y/U/V) | mm | 400x300x70x70 | 600x400x70x70 |

| Travels Z | mm | 300 | 400 |

| Max.Cutting taper | ° | ±15°/80mm(with guider) | ±15°/80mm(with guider) |

| Size of work tank(Internal effective size) | mm | 960x550 | 1190x650 |

| Max.Cutting thickness | mm | 300 | 400 |

| Workpiece | |||

| Max.Workpiece weight | kg | 500 | 800 |

| Max.Workpiece size | mm | 960x550x300 | 1190x650x400 |

| Power supply system | |||

| Strandard configuration | 3x380V 50/60Hz 3KVA | 3x380V 50/60Hz 3KVA | |

| Generator and machining technology | |||

| Max.Machining current | A | 15 | 15 |

| Max.cutting speed | mm²/min | 300 | 300 |

| Best roughness | μm | Ra≤0.8 | Ra≤0.8 |

| Size of water tank | mm | 900x500x570/180L | 900x500x570/180L |

| Size of machine | mm | 2040X1600X1830 | 2400x1890x2060 |

| Weight of machine | kg | 2280 | 2840 |

Intelligent improvements and different patents

Ready to conquer the European market

Patented Newest EDM Wire-cutting Technologies

Improved precision, speed, reliability and performance!

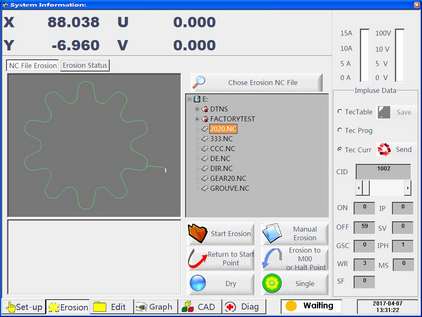

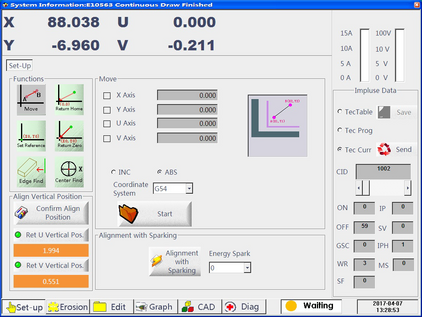

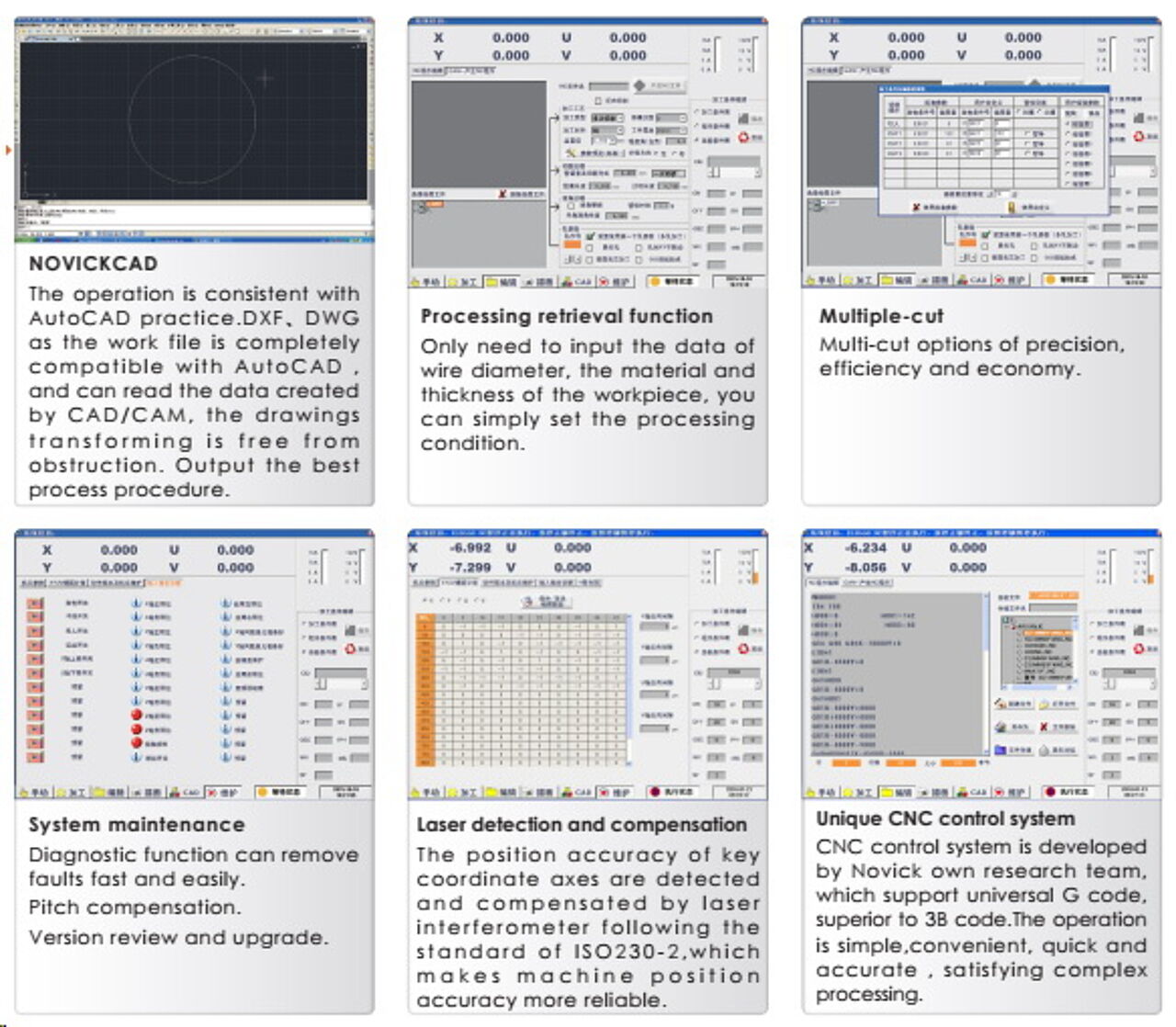

Controller including CAD

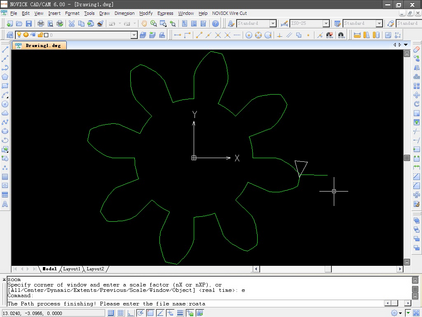

Novick CAD software system brings you a user-friendly experience

-

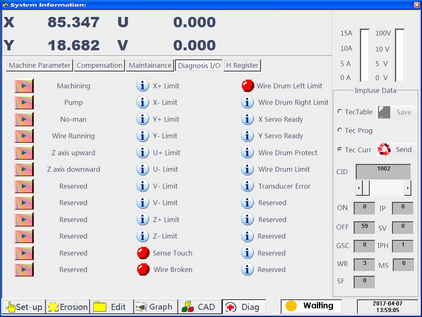

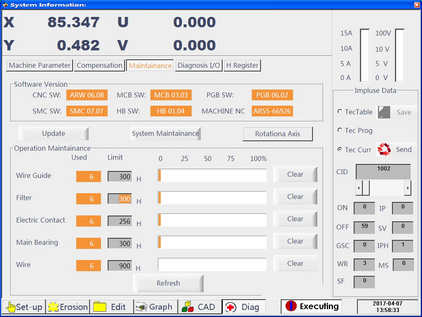

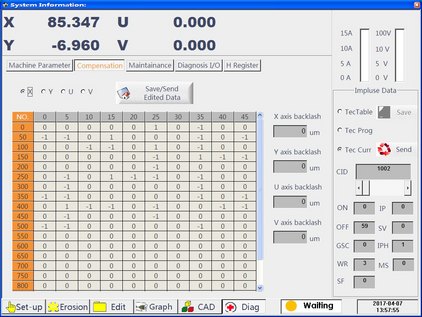

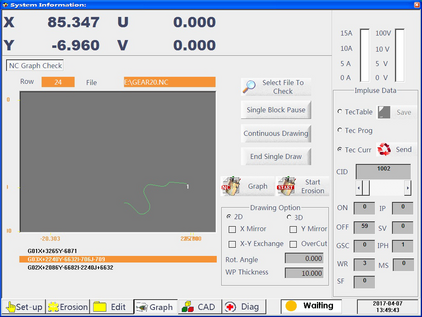

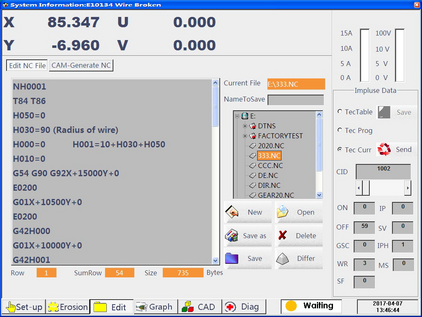

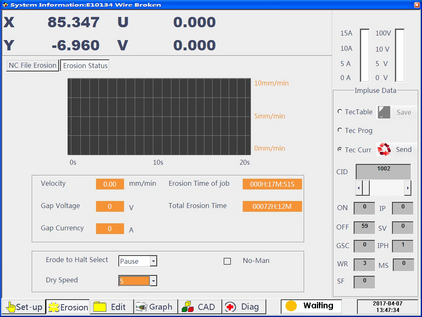

6 pages of screens, consisted of Manual, Erosion, Edit, Graph, Diagnostic, CAD/CAM offer very friendly man-machine interface

-

Real-timely multi-tasking control software makes it possible to do preparations for next jobs during erosion.

-

The friendly man-machine interface can meet the needs both for beginners and experienced operators.

-

NC programming takes the standard ISO G/M code .

-

Integrated CAD/CAM programming system allows operators to design NC programs automatically by key-in drawings in machine or receiving drawing files in DXF format from serial communication interfaces.

-

With powerful CNC function, edge Find,Center Find, Automatically.

-

With USB interface and LAN communication interface, the machine can exchange datum with programming computers or control center conveniently.

Download here your latest Catalogue of this machine!

Novick Catalogue download

Catalogue Novicut M

High Speed wire cutting