What is the easiest way to remove a 3d print from a bed? Simple Method for removing sticky 3d-printed Objects from the Build-Plate. Removing your 3D Print from the Build Plate. Removing your model from the build plate.How to remove your print from the build plate.How To Remove 3D Prints From The BedIs your 3D print stuck to the bed?How to separate the parts from their base plate.How to Remove Support Structure from 3D Prints.Best way to remove 3d printed parts from the base plate!

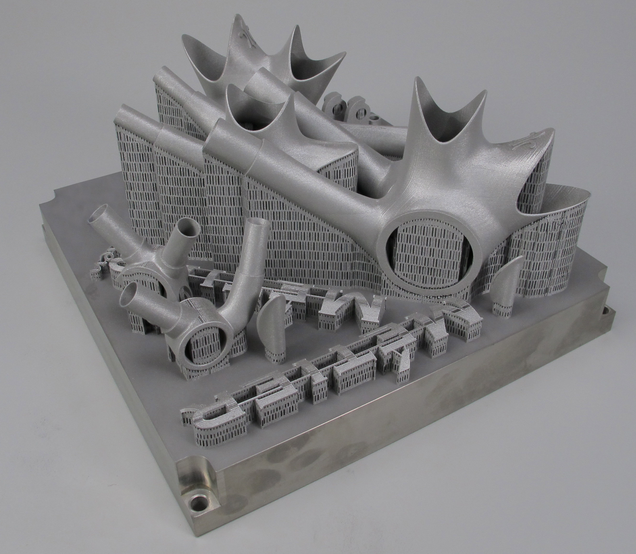

Novicut-M AM3D: best solution for your 3D AM metal parting

SPECIAL MACHINE FOR ADDITIVE MANUFACTURING

We offer THE BEST Cut-off tool for 3D Metal Additive Manufacturers: affordable, high speed, reliable, efficient and super economical.

ADDITIVE MANUFACTURING -- METAL 3D PRINTING

Worlds best solution for easy, reliable and economical cutting off your workpieces from the Metal 3D printer's base plate

Novicut-M AM3D:

best solution for your 3D AM metal parting!

Our Machine do remove fast and at a fraction of the cost of the others, easily and economically all your parts from their base-plate made by following processes :

AM : Additive Manufacturing

RP : Rapid Prototyping

Power Bed Fusion

SLS : Selective Laser Sintering

SLM: Slective Laser Melting

DMLS : Direct Metal Laser Sintering

EBM : Electron Beam Melting (Laser Cusing)

Metal Binder Jetting

BEST BASE PLATE REMOVAL TOOL: NovicutM-AM3D

Novick Europe introduces its Novicut-M-AM3D series

Additive manufacturing cutting Machines

High-performance wire cutting machine for separating components made of materials that are easy to difficult to machine from their base plate using an additive manufacturing process.

Designed as an affordable and reliable wire EDM solution

to economically remove metal 3D-printed parts from their build plate.

Based on our standard machine build since more than 20 year,

The Novicut-M-AM3D can handle build plates ranging from

100 x 100 mm to 500 x 1000 mm.

Bigger sizes on demand!

-

The Wire EDMs are equipped with a reusable Molybdenum wire feature, which quickly moves inexpensive wire from the source capstan, to the receiving capstan, and then back again so that the wire is continuously moving back and forth through the workpiece.

-

The rapid speed of the wire (10 - 50 times higher than normal brass wire cutting machines) creates its own flushing so high-pressure pumps are not required.

-

The Molybdenum wire is very resistant to wire breaks, offering an advantage over the brass wire that is typically used in a wire EDM.

-

The dielectric used is a mixture of water and oil to reduce oxidation on the part surfaces.

NOVICUT-M AM3D : Wire EDMs Designed for Metal 3D-Printed Part Cut Off

We offer a cutting process that is:

Stable and reliable

Fast cutting:

Medium speed for hard materials is around 150-220 mm²/min = 9000 - 13.200mm²/hour

High speed for hard materials is till 360 mm²/min = 21.600mm²/hour

Handle ALL hard conductive materials

Reliable : based on an 30 years existing technology

With a minimum loss of material (0.18mm)

Precise : +- 0.005 mm

Zero-force cutting: never damage a part

With low investment

At a ridiculous low cutting cost per hour

Easy to operate

Flexible : fit for most of the base plates of any brand

We reuse our wire continiously

Almost no wire breakage problem by powder inclusions

The EDM range is intended as an affordable option for removing metal 3D-printed parts from build plates.

Our novicut M -AM3D offers the fastest and higest ROI

Your machine pays back itself with the highest Return on Investment on the machine market

Compare sawing, wire cutting and moly wire cutting for removal of AM parts

Solutions available to remove your parts from the baseplate

| 400 x 400 mm baseplate sample | Manual bandsaw | Automatic bandsaw | Special AM bandsaw | Wire cutting machine | novicut-M AM-3D |

| investment | 8-15.000€ | 24 - 40.000,€ | 80 - 120.000,€ | 90 - 150.000,€ | 35 - 50.000, € |

| operator needed for | all time | setup - collect | setup | setup-collect | setup - collect |

| Thickness of cut : material losses | 1- 2 mm | 1,4 - 2,8 mm | 0,9 -1,2 mm | 0,3mm | 0,18mm |

| Cutting time | Short | Short | Short | very long | Average - short |

| Cutting forces on part | big | Big | Big | None | None |

| Precision of positioning | 0,5mm | 0,5mm | 0,3mm | 0,01mm | 0,01mm |

| Angle deformation compensation | no | no | no | yes | yes |

| multiple plates loaded in machine possible (unmanned long run at night) | no | no | no | yes | yes |

| Dustfree - healty | no | no | yes | yes | yes |

HIGH SPEED WIRE CUTTING MACHINES

The EDMs are equipped with a reusable Molybdenum wire feature, which quickly moves inexpensive wire from the source capstan, to the receiving capstan, and then back again so that the wire is continuously moving back and forth through the workpiece. The rapid speed of the wire (till 50 times faster than a normal wire cutting machine) creates its own flushing so high-pressure pumps are not required. The Molybdenum wire is very resistant to wire breaks, offering an advantage over the brass wire that is typically used in a wire EDM. The dielectric is a mixture of water and oil to reduce oxidation on the part surfaces.