Affordable High Precision

Closed loop measuring system: 0,25µm Heidenhain linear scales

A veritable concentration of innovation and technology, the Noviform-P® range indeed merits its name.

By giving you the opportunity to greatly increase your useful machining time, the new Noviform-P® machines allow you to take pole position in your markets.

High precision, productivity and power all in one, stuffed with all the features available

Closed loop direct absolute measuring system with precision of 0,25 micron

4 axis cnc control + orbit II ® function + expert3 + C-axis + ATC + DSAPCS pro

Smallest increment 0.001mm, surface roughness achievable Ra = 0,10um with super mirror finish

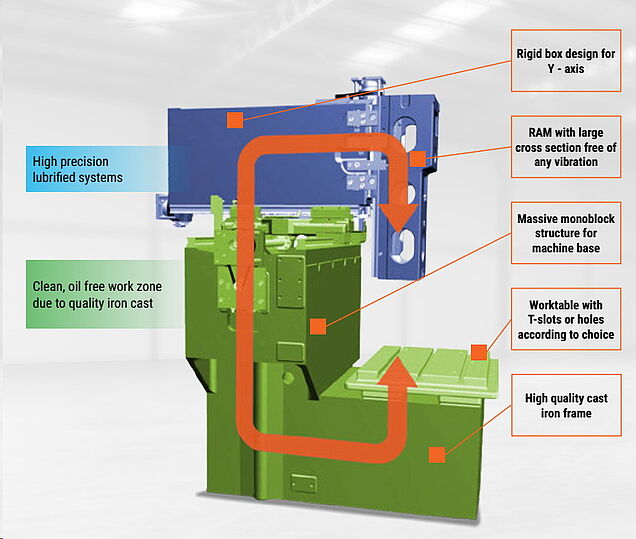

Nothing beats solid steel except ...

MORE solid steel in a single piece casted C-frame Bed.

The exceptionally heavy-duty C-frame cast iron machine bed, only the best, top-flight linear guides and precision assembly ensure the best die sinking cutting results in the long term.

Even more precise axis movement – whatever the load.

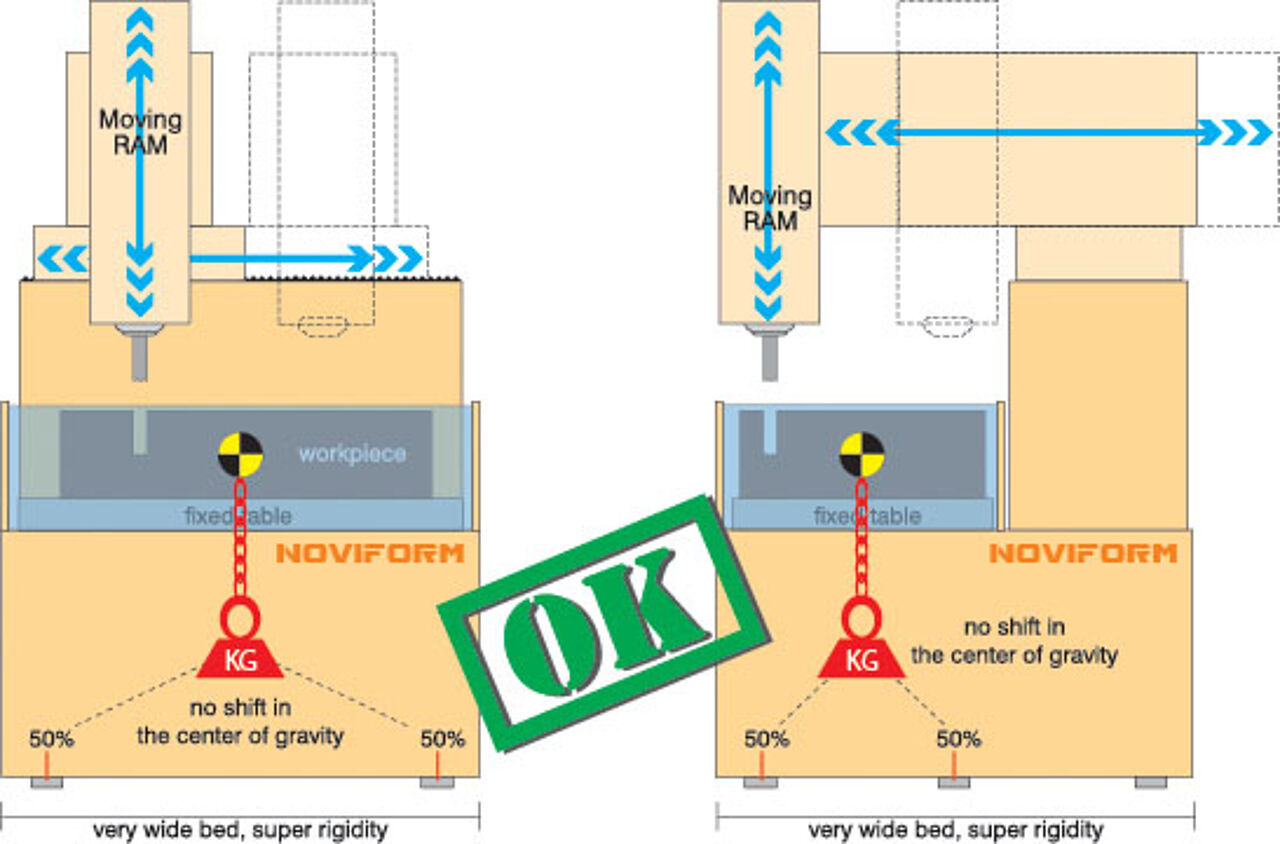

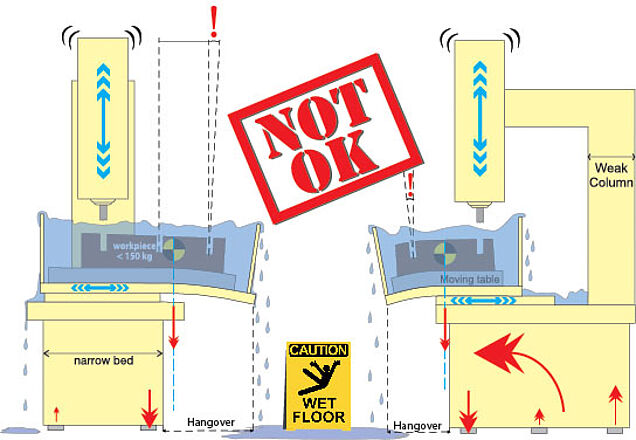

No overhang!!

Why is our machine more stable?

Swiss C-frame design.

The mechanical design of the Novick machines is that of the fixed bench: combining robustness and accuracy.

The part to be machined rests directly on the independent fixed table of the meehanite casted vibration absorbing main frame.

This design, where the part is static, enables very heavy parts to be loaded without affecting accuracy. The precision components of the machine are used solely to move the electrode guides. Protected from dirt, shocks and stresses, they work permanently in an ideal situation to ensure durable accuracy. The fixed bench combines robustness and accuracy and keep all moving high precision components above and out of the working zone.

Traditional Swiss design and Japan based manufacturing techniques create machines where the performances of it do not change even after years of use. This longevity is due, to a great extent, to the manufacturing quality.

The very high accuracy surface grinding of the guiding and mounting surfaces contributes to this durable accuracy.

Before it is delivered, each machine is subjected to a laser test, which checks, in accordance with the VDI 3441 standard, that on all the axes positioning accuracy is situated within the specified tolerances.

Our C-frame beats them all!

Stronger, cleaner, more stable, more precise, less problems, higher load, ...

Do you want this in your workshop?

High Precision Die sinking machine

Affordable High Precision

| Noviform-P Series | Unit | Noviform-500P | Novifrom-700P |

|---|---|---|---|

| Workspace | |||

| Size of worktable | mm | 600×400 | 800×600 |

| The distance between Z-planed and worktable | mm | 300~600 | 260~660 |

| Travels X/Y/Z | mm | 500×300×300 | 700×400×400 |

| Electrodes and workpiece | |||

| Max.electrode weight | kg | 70 | 100 |

| Max.workpiece weight | kg | 1000 | 2000 |

| Max.workpiece size | mm | 800×500×300 | 1100×700×450 |

| Axes | |||

| Manual speed X/Y/Z | m/min | 4 steps adjustable,the 4th is the highest | 4 steps adjustable,the 4th is the highest |

| Pitch software compensation X/Y/Z | mm | 5 | 5 |

| Guide rail type X/Y/Z | Linear rolling guide | Linear rolling guide | |

| Min.dip angle | μm | 30 | 30 |

| CNC | |||

| Control system | Based on industrial control system | Based on industrial control system | |

| Operating system | Windows | Windows | |

| Disk on chip | More than 32GB | More than 32GB | |

| Input type | MDI/USB /LAN | MDI/USB /LAN | |

| Monitor | Touch screen LCD monitor 17" | Touch screen LCD monitor 17" | |

| Programable axes | XYZC4-axes | XYZC4-axes | |

| (controlled simultaneously)(optional: C axes) | (controlled simultaneously)(optional: C axes) | ||

| Interpolation | Liner/arc | Liner/arc | |

| Orbit type | Free arbit/servo orbit | Free arbit/servo orbit | |

| Orbit mode | Circle/square/vector/polygon | Circle/square/vector/polygon | |

| Remote control center | |||

| Function keys | Selection and movement of the axes/ | Selection and movement of the axes/ | |

| movement speed and single step/ | movement speed and single step/ | ||

| pump/start/end/pause/edge find/ | pump/start/end/pause/edge find/ | ||

| hole center find/half movement | hole center find/half movement | ||

| back to zero/ dop open | back to zero/ dop open | ||

| Electric cabinet and processing | |||

| Standard power | 3×380V 50 / 60Hz 10KVA | 3×380V 50 / 60Hz 10KVA | |

| Max.machining current | A | 50(optional:100A) | 50(optional:100A) |

| Processing condition storage capacity | 1000 | 1000 | |

| Max.machining speed | mm³/min | 380±10%(50A)/550±10%(100A) | 380±10%(50A)/550±10%(100A) |

| Best roughness(Ra) | μm | Ra 0.1 | Ra 0.1 |

| Options | |||

| Extended current module | A | 100 | 100 |

| AC servo system | Panasonic | Panasonic | |

| Embedded C axis | kg | Max.electrode weight 15kg | Max.electrode weight 15kg |

| Closed Loop measuring | |||

| Linear scales X/Y/Z | HEIDENHAIN resolution 0.25μm | HEIDENHAIN resolution 0.25μm | |

| (optional:AC servo system) | (optional:AC servo system) | ||

| AEC: automatic electrode changer | AF50:4 forks AF70: 5 forks | AF50:4 forks AF70: 5 forks | |

| Machine Dimensions | |||

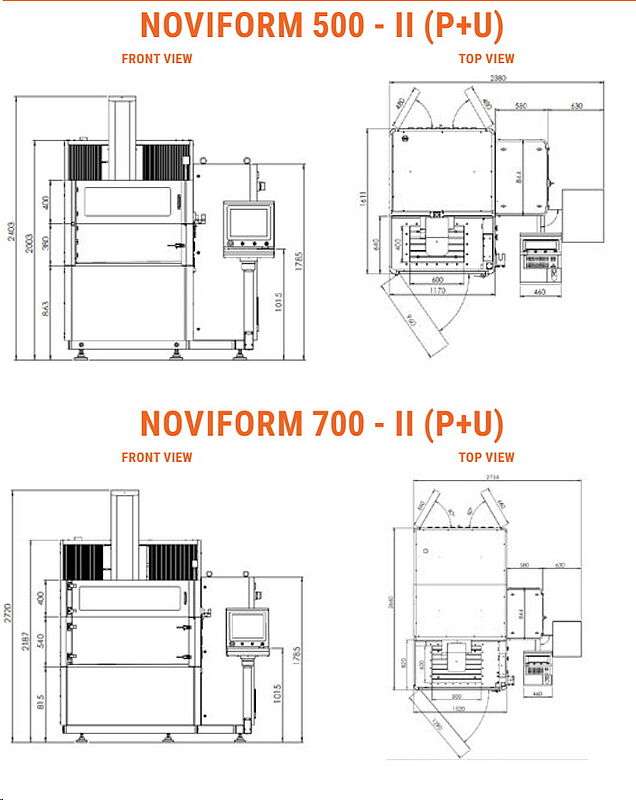

| Size of machine | mm | 2380×1611×2403 | 2734×2660×2720 |

| Weight of machine | kg | 2300 | 4600 |

| Customization | |||

| 1.Machinre configuration | |||

| 2.Machine Performance | |||

| 3.Special function | |||

| 4.Individual color | |||

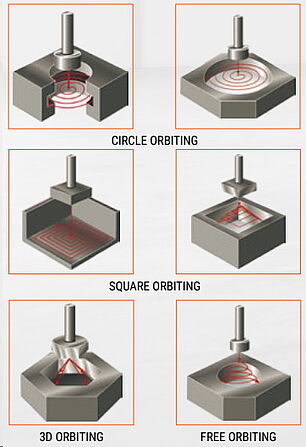

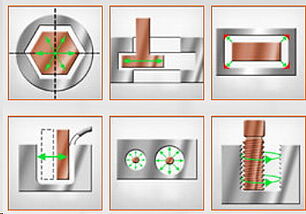

Orbit-II Pro-technology

Every Noviform® Die sinker is boosted with the new OrbitII Pro-technology providing higher machining precision and superior surface quality Noviform®Orbit II Pro Technology:

- Reduces machining time with 50% and electrode wear with 70%

- Improve surface finish quality with 50%

- Breaks through traditional restriction

- Upgrades the accuracy of the products•Increases efficiency and productivity

- Easy with intelligent design

- Fully tested through shock and vibration testing•Cuts at 45° for corner-sharpening

- Makes it easy to engrave a T-type channel

- Preventing build-ups of debris and deformation in boring a deep hole & big plane

- Hexagon machining

- 100% of Screw Mould Junction

- Different sizes of cavity machining can be done using just one size of electrode

Orbit-II-Pro makes the difference

Conventional orbital machining (Spherical Orbiting or planetary movement of the electrode) is done consecutively, from point to point, along the targetedshape and the electrode movement is not smooth,resulting in unstable machining. The spherical orbitpattern is an option found on many advanced CNC sinkers. Spherical orbit patterns are not possible with mechanical orbiters or many of the available electronicspindle-mounted orbiters.

Contour-orbiting and C-axis orbiting (opt)

With our newly developed second generation Orbit II Pro technology, machining is done withan electrode that is in constant motion, following the targeted shape. This results in highly stable machining. The newly developed Orbit II Profunction smoothly guides electrode movement for uniform surfaces without unevenness. This advanced machining technology, in which the electrode is in motion continuously, results in stable finish machining with improved precision and quality.

Portable Hand-controller with position display

Positioning with the electronic handwheel – Delicate axis traverse

Particularly with the portable handcontroller you are always close to the action, enjoy a close-up view of the setup process, and can control the infeed responsively and precisely.

The portable handcontroller with axis position display is particularly helpful for when you have to work close to the machine’s working space. The axis keys and certain functional keys are integrated in the housing. In this way you can switch axes and set up the machine at any time— regardless of where you happen to be standing. If you no longer need the handwheel, just attach it to the machine somewhere by its built-in magnets.

Dimensions and layout

Download here your latest Catalogue of this machine!

Novick Catalogue download

Catalogue Noviform P

High Precision die sinking