Do you have following problems in your 3D metal printing?

Novicut-M 3D can solve this problems for DMLS, SLS, SLM, DMP, EBM.

How to remove 3D Metal Prints from the Bed?

How to remove 3D Metal Prints from the Base Plate?

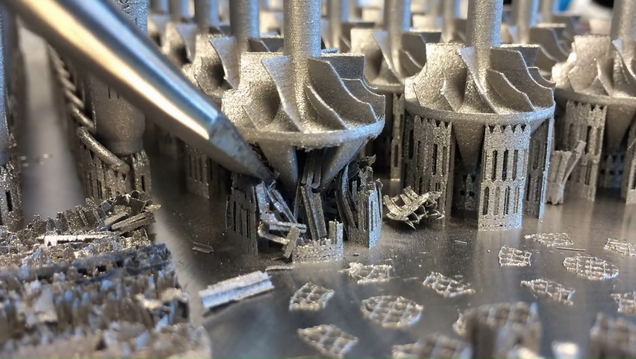

How to remove the printed metal support from 3D Metal Printed parts?

How to cut off the 3D printed metal part from the machine base plate?

Novicut-M-3D: Affordable high-tech solution for the additive manufacturing industry

Novick Europe has released the Novicut-M 3D-removal line, an affordable wire EDM specific to remove the base plate from 3D metal printing applications.

This model is the latest addition to Novick’s M range of versatile economical wire EDM machines. As the capacity of additive machines continues to increase, it becomes increasingly important for wire EDM offerings to continue to accommodate the growing baseplate and support sizes, Novick says. With a 300 till 500-mm Z-axis stroke, the Noviform-M-3d is suited for the postprocess removal of 3D-printed parts, as well as the production of large molds and aerospace components.

Like other models in the series, the WEDM offers an improvement to the company’s patented molybdenum re-usable wire technology.

With this machine an affordable solution becomes available for every additive manuafacturer.

Advantages of our system:

-

2D, 3D, 4D, 5D cutting possible

-

Non contact cutting

-

No single force is applied on the part

-

Cutting wide is max 0,20 mm

-

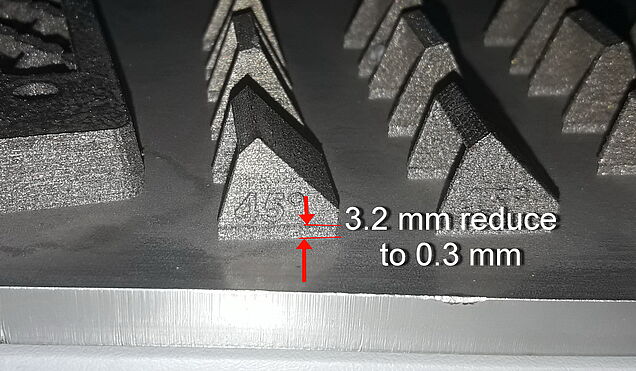

High precision cutting +-0,005 mm

-

Cutting off the parts from the base plate with only 0.2 mm losses

-

Affordable machine

-

Very low cutting cost (reusable molybdenum wire)

-

Different models and dimension available

-

High tech for a low price

-

Possible to cut-off in 3D, the support structures at a precison of 10µm

-

Low maintenance cost.

-

No dust

-

Accept cad files

-

Can load more than one plate for long unmanned running

-

possible to mount more base plates on the table for long run

-

C-axis is possible to cut REAL-3D

-

Rotary pallet system possible

-

Can run long time UNMANNED

OUR 3 MOST COMMON MODELS

Bigger model available

| machine | Novicut-400M-III | Novicut-600M-III | Novicut-650M-II | |

| Size of worktable | mm | 590x440 | 800x580 | 920x620 |

| Travels(X/Y/U/V) | mm | 400x300x70x70 | 600x400x70x70 | 650x500x36x36 |

| Travels Z | mm | 250 - motorized | 350 - motorized | 450 - motorized |

| Max.Cutting thickness | mm | 300 | 400 | 500 |

| Max.Cutting taper | ° | ±15°/80mm(with guider) | ±15°/80mm(with guider) | ±10°/80mm(with guider) |

| Size of work tank(Internal effective size) | mm | 960x550 | 1190x650 | 1300x800 |

| Workpiece | ||||

| Max plate size | mm | 300 x 300 (300 x400) | 400 x 400 (400 x 600) | 500 x 500 (500 x 650) |

| Max.Workpiece weight | kg | 500 | 800 | 1200 |

| Max.Workpiece size - without base plate | mm | 300 x 300 x 400H | 400 x 400 x 600H | 500 x 500 x 650H |

| Power supply system | ||||

| Strandard configuration | 3x380V 50/60Hz 3KVA | 3x380V 50/60Hz 3KVA | 3x380V 50/60Hz 3KVA | |

| Generator and machining technology | ||||

| Max.Machining current | A | 15 | 15 | 15 |

| Max.cutting speed | mm²/min | 350 | 350 | 350 |

| Best roughness | μm | Ra≤0.8 | Ra≤0.8 | Ra≤0.8 |

| Size of water tank | mm | 900x500x570/180L | 900x500x570/180L | 1300x800x590 |

| Size of machine | mm | 2040X1600X1830 | 2400x1890x2060 | 2340x2025x2580 |

| Weight of machine | kg | 2280 | 2840 | 3215 |

Our 3D metal print cutting machine can handle :

We cut every metal part in following materials (and much more) from the base plate:

-

TOOL STEEL (MS1 - 1.2709)

-

STAINLESS STEEL (PH1 - 1.4540)

-

STAINLESS STEEL (1.4542)

-

STAINLESS STEEL (1.4404)- 316L

-

STAINLESS STEEL (CX) - CORRAX

-

Maraging STEEL MS1 1.2709

-

STEEL-NICKEL (INVAR 1.3912)

-

ALUMINUM (ALSI9CU3)

-

ALUMINUM (ALSI10MG)

-

Aluminum AIF357

-

ALUMINIUM (ALMGSI0.5)

-

ALUMINIUM (3.2371 | AlSi7Mg)

-

INCONEL (IN625)

-

INCONEL (IN718)

-

Hastelloy X® (2.4665)

-

COBALT CHROME (COCRW)

-

COBALT CHROME (COCR75)

-

NICKEL-CHROME (NI625)

-

NICKEL Based (NI718)

-

NickelAlloy IN718 / 2.4668

-

NickelAlloy HX / UNS 06002

-

COPPER (RS-COPPER)

-

COPPER (CUNI2SICR)

-

BRASS (RS-BRASS)

-

TIANIUM GR. 1 (3.7025)

-

TITANIUM GR. 5 (TI6AL4V – 3.7164)

-

TITANIUM GR. 23 (TI6AL4V – 3.7165 ELI)

-

ZINK (ZAMAK 5)

-

ZAMAK (Z430)

-

COPPER - INDUCTORS

-

COPPER-ALUMINIUM (2.0921 | CuAl8)

-

......... and much more

Cutting your Additive Manufacturing Production Time

Novicut-M 3D-AM Significantly Improves Productivity of your Metal Additive Manufacturing

Contact us for more information on our solution for additive manufacturing removal techniques.

Affordable, Precise and efficient!

DMLS, Direct Metal Laser Sintering, Rapid Prototyping, Metal powder bed fusion, SLS, Selective Laser Sintering, SLM, selective laser Melting, DMP, Direct metal printing, DIRECT METAL PRINTERS (DMP), FUSED DEPOSITION MODELING (FDM) PRINTERS, LARGE PLATFORM FUSED DEPOSITION MODELING PRINTERS, SELECTIVE LASER SINTERING (SLS), metal 3d printing, 3d metal printing, metal am, metal additive manufacturing, 3d additive manufacturing, EBM, electron beam melting, cuttof base plate, cut off metal support structures, laser cusing, 3D Metal Melting, metallic 3D printing (M3DP), Laser Wire 3D Printing, metallic 3D printing (M3DP), M3DP, wire and arc additive manufacturing (WAAM), WAAM, AM technology, metal AM, metal additive manufacturing (MAM), Directed Energy Deposition (DED) , Laser Metal Deposition (LMD), directed energy deposition (DED), powder-bed fusion (PBF), Joule Printing, Metal 3D Printing, Laser Metal 3D Printing, Large Additive Subtractive Integrated Modular Machine, FDM - Fused Deposition Modelling, Laser Beam Powder Bed Melting, LBM , Laser Beam Melting,

What is the easiest way to remove a 3d print from a bed? Simple Method for removing sticky 3d-printed Objects from the Build-Plate. Removing your 3D Print from the Build Plate. Removing your model from the build plate.How to remove your print from the build plate.How To Remove 3D Prints From The BedIs your 3D print stuck to the bed?How to separate the parts from their base plate.How to Remove Support Structure from 3D Prints.Best way to remove 3d printed parts from the base plate!