EDG - Electric Discharge Grinding

In the present work conditions, the processes like conventional diamond grinding, electric discharge machining (EDM), and electric discharge grinding (EDG) are compared on the basis of material removal rate (MRR) and surface finish (Ra).

EDG is the hybrid process of EDM and grinding and hence utilizes the benefits of both processes to give better MRR and surface finish than the parent processes. The MRR achieved in the EDG process is up to 50 times higher, and the surface roughness is at least 4 times better than the EDM process. The surface finish obtained by the EDG process is at least 4.5 times better than the conventional diamond grinding process and 3 times lower than cryogenically cooled conventional diamond grinding process. Surface and subsurface cracks, pit formation, and micropores were observed after conventional diamond grinding and EDM, but no such drawbacks were found on the selection of proper process parameters in case of the EDG process.

Hence, surface finish and MRR obtained in EDG are better than EDM and the conventional diamond grinding process.

Novigrind 3D

Tool performance and toolmaking technology advance hand-in-hand. As advanced tool materials like PCD gain favor in the marketplace, toolmakers will find quicker, better and more cost- efficient ways to produce those tools. Combining technologies like electrical erosion and conventional grinding in our EDG machine is a good example of matching technologies to the challenge of making superhard tools.

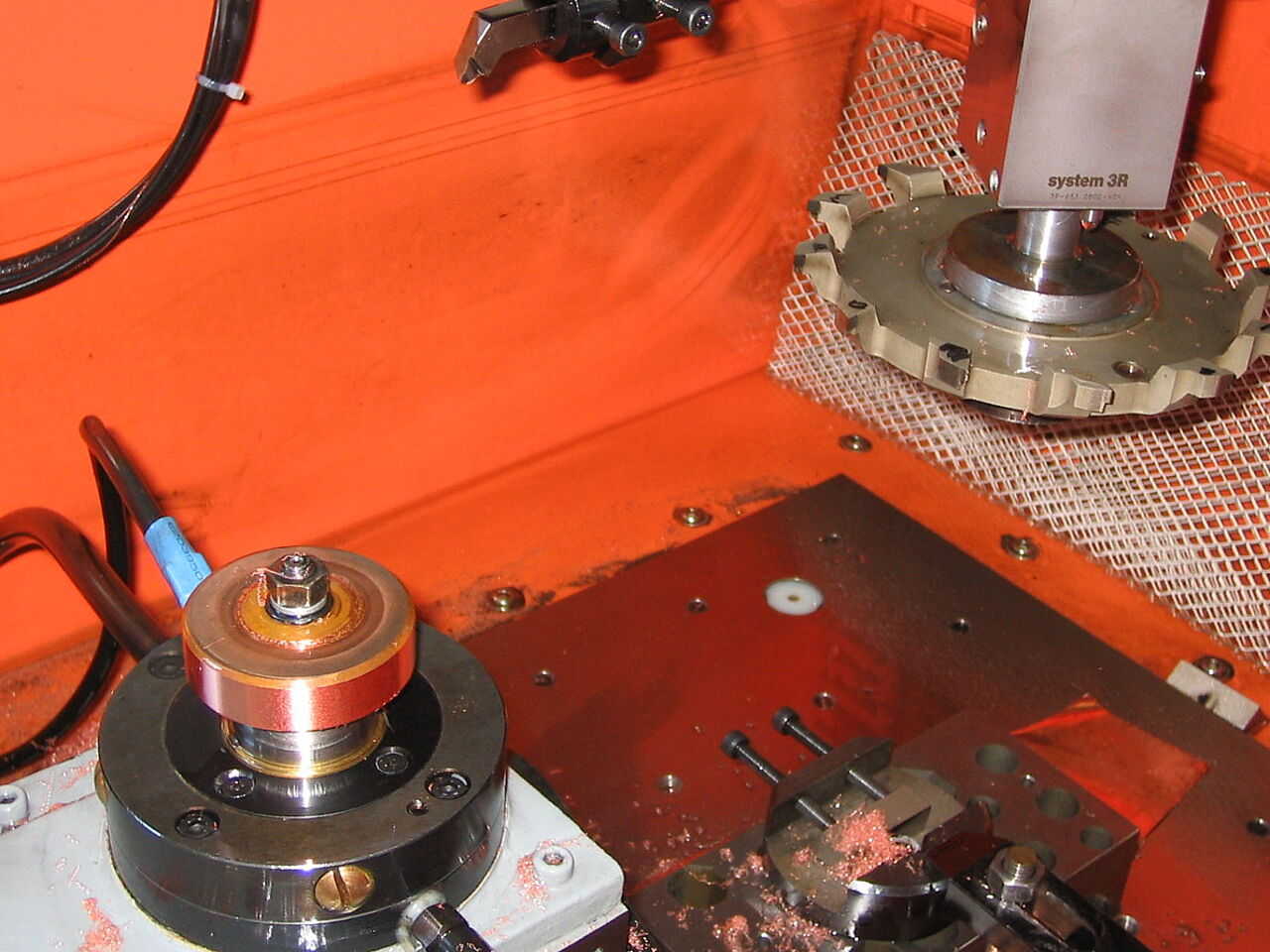

Our new EDG-machine allows the transfer of extremely sophisticated forms, finest cut-ins, delicate profiles, and small radii and surfaces onto round pieces completely contactless, i.e., without exerting any force onto the workpiece. The rotational axis is employed wherever small, fine punctures or small flanging radii cannot be achieved by mere turning or round grinding.

The rotational axis offers major advantages, in particular for grinding wheel dressing tools, by allowing the transfer of profiles with very delicate inside radii of, e.g., r=0.05mm. This procedure results in profile accuracies in the µ range with high true running accuracy. The process works on electrically conducting workpieces only. Another advantage is that EDM grinding also prevents heat introduction during the working process. As a result, the material’s structure remains unchanged, which frequently occurs when employing turning or round grinding processes.

Superhard versus superhard

Toolmakers combine technologies to meet growing demand for PCD (Poly-Crystalline Diamond) tools. The cutting edge geometries and final dimensions of cutting tools are typically produced on CNC tool and cutter grinders. Tools with PCD cutting edges, however, pose a challenge. Grinding PCD pits the hardest known substance (diamond) against an equally hard grinding wheel. The resulting virtual standoff consumes excessive time and wheels.

“In PCD grinding, what you are doing is taking two substances of equal hardness and trying to have one remove the other, as result you end up having an almost one-to-one wear, which becomes very expensive.”

Electrical Discharge Grinding (EDG), is an efficient and accurate way to remove PCD when manufacturing or regrinding PCD tools. One way to limit expense is removing PCD via electrical erosion, in the form of either Electrical Discharge Grinding with a tungsten-copper disc or with a wire-EDM. The cobalt binder in PCD acts as a conductor for the electrical energy. The main benefit of using an EDG or a wire EDM to shape PCD tools is cost savings: you are using a noncontact, electrical charge to remove material instead of wearing down a diamond wheel.

PCD cutting edges can be shaped via Electrical discharge grinding (EDG) with a tungsten-copper disc. The cobalt binder in the PCD tool conducts the electrical energy, and the electrical charge removes the diamond material without any hard contact.

Wire EDM can offer an advantage compared to rotary erosion because it can create small inside radii and other complex tool features that a rotary disc can’t. On the other hand, the rotary electrode is a thick, stiff piece of tungsten copper that, unlike a wire, does not offer any deflection. It is much more rigid erosion, and all things being equal, you have a faster material-removal rate.